Description

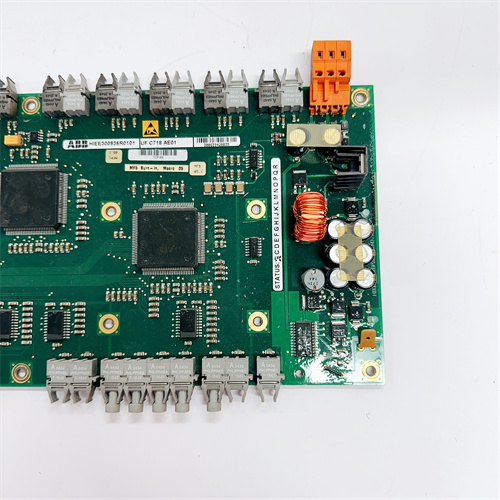

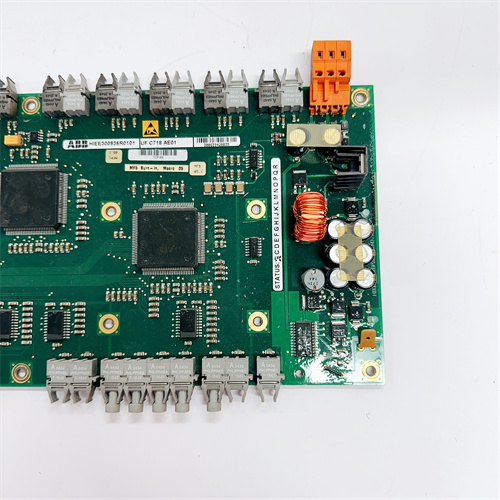

1. Product Description

Since ABB UFC718AE01 is deeply compatible with the ABB AC 800M system, it can seamlessly connect with other components in the same series (e.g., the AI801 analog input module) and support data interaction with SCADA/MES upper-level systems, significantly reducing system integration complexity. The advantages of ABB UFC718AE01 are particularly prominent in scenarios with frequent load fluctuations — such as temperature control of boilers in thermal power plants, pressure regulation of distillation towers in refineries, and liquid level stabilization of reactors in chemical plants — where it consistently maintains stable control performance.

In addition, ABB UFC718AE01 has undergone rigorous testing for vibration resistance, electromagnetic interference immunity, and extreme temperature tolerance, meeting industrial-grade reliability standards. It is also equipped with extended diagnostic functions that can real-time monitor component aging status and signal quality, helping maintenance personnel identify faults in advance and avoid unplanned downtime.

2. Technical Parameters

| Parameter Category | Specific Specifications |

|---|---|

| Module Type | Digital PID Control Module |

| Number of Control Loops | 8 independent PID loops (can control 8 processes simultaneously) |

| Input Signal Types | Analog: 4-20mA, 0-10V DC (compatible with temperature/pressure sensors); Differential: ±5V DC, ±20mA (for high-precision flow measurement) |

| Output Signal Types | Digital Output: 8 channels (relay/transistor type, for signal triggering and switching); Analog Output: 4 channels (4-20mA, for stepless adjustment of actuators) |

| PID Regulation Performance | Proportional Gain (P): 0.1-1000; Integral Time (I): 0.1-3600s; Derivative Time (D): 0-1000s; Supports standard PID, adaptive PID, and cascade control |

| Data Processing Speed | Regulation cycle: 10ms/cycle (ensures rapid response to parameter deviations) |

| Operating Environment | Temperature: -40°C to +70°C (suitable for outdoor/indoor installation); Humidity: 5%-95% (no condensation); Protection Class: IP20 (suitable for DIN rail mounting in cabinets) |

| Power Supply & Communication | Power Supply: 24V DC (maximum load current: 150mA); Communication Interface: Supports PROFINET/Ethernet/IP (communication with ABB AC 800M PLC) |

| Certification Standards | IEC 61508 (SIL 2 Functional Safety Certification), ATEX (Zone 2 Hazardous Area Certification), UL, CE |

3. Advantages and Features

- Multi-Loop Control Integration: A single ABB UFC718AE01 supports 8 independent PID loops, enabling simultaneous management of multiple process parameters (e.g., temperature, pressure, and liquid level of the same boiler). Compared with single-loop modules, it reduces the number of devices, lowers cabinet space occupancy, and cuts procurement costs.

- High-Precision Regulation Capability: With a 10ms regulation cycle and adaptive PID algorithms, ABB UFC718AE01 can quickly respond to parameter fluctuations. It is especially suitable for scenarios with strict process precision requirements (such as semiconductor manufacturing and pharmaceutical production), where it can control parameter deviations within an extremely small range.

- High Safety Level: Certified to IEC 61508 SIL 2, it meets the functional safety requirements of hazardous industries like oil & gas and chemical engineering, effectively avoiding safety accidents caused by control failures.

- Intelligent Diagnostic Functions: It real-time collects data such as channel status, actuator wear levels, and sensor signal quality, then uploads the data to the SCADA system. This supports predictive maintenance and reduces the probability of sudden faults.

- ABB Ecosystem Compatibility: Perfectly compatible with the ABB AC 800M PLC and Control Builder M configuration software, ABB UFC718AE01 requires no additional driver development, simplifying parameter configuration, calibration, and firmware update processes, and lowering maintenance thresholds.

4. Application Case Studies

- Energy Sector (Thermal Power Plants): In the pulverized coal boiler system of a thermal power plant, ABB UFC718AE01 controls 8 key parameters simultaneously — flue gas temperature, drum water level, main steam pressure, fuel flow, primary air pressure, etc. By dynamically adjusting fuel supply and air intake, it maximizes combustion efficiency while reducing pollutant emissions such as NOₓ.

- Oil & Gas Refining Sector: In the distillation tower process of a refinery, fluctuations in crude oil composition cause changes in tower temperature and pressure. ABB UFC718AE01 can real-time adjust the cooling water volume of the overhead condenser and the heating power of the bottom reboiler, ensuring the distillation purity of products like gasoline and diesel meets standards consistently.

- Chemical Production Sector: In polymer reactors, ABB UFC718AE01 controls reaction temperature, pressure, and catalyst injection volume. Through cascade PID algorithms, it avoids local overheating, ensures uniform molecular weight distribution of polymers, and improves product quality consistency.

- Municipal Water Supply Sector: In the clean water tank and water supply network system of a large water treatment plant, ABB UFC718AE01 monitors tank water level and network pressure. It automatically increases the power of water supply pumps during peak water consumption periods and reduces energy consumption during off-peak periods, balancing water supply pressure and energy-saving needs.

5. Comparison with Competitors

| Comparison Dimension | ABB UFC718AE01 | Siemens S7-400 FM 458-1 DP | Emerson DeltaV PK Controller |

|---|---|---|---|

| Number of PID Control Loops | 8 channels | 4 channels | 6 channels |

| Regulation Cycle | 10ms/cycle | 20ms/cycle | 15ms/cycle |

| Functional Safety Certification | IEC 61508 (SIL 2) | IEC 61508 (SIL 1) | IEC 61508 (SIL 2) |

| System Compatibility | ABB AC 800M | Siemens S7-400 | Emerson DeltaV |

| Reference Price | Medium | High | High |

6. Selection Recommendations

- Prioritize System Compatibility: If your existing or planned automation system is the ABB AC 800M, prioritize ABB UFC718AE01 to avoid cross-brand compatibility issues and reduce integration difficulty and long-term maintenance costs.

- Match Process Complexity: If you need to control 5-8 process parameters simultaneously (e.g., multi-loop reactors, large boilers), the 8 PID loops of ABB UFC718AE01 can meet the demand without additional modules. For 1-4 loops, consider more cost-effective single-loop modules.

- Safety Level Requirements: For scenarios involving ATEX Zone 2 hazardous areas or chemical processes requiring SIL 2 levels (e.g., toxic medium reaction processes), ABB UFC718AE01 is a more compliant choice, while the Siemens FM 458-1 DP (SIL 1) cannot meet high safety demands.

- Environmental Adaptability: If the application scenario has a temperature range beyond -10°C to +60°C (e.g., outdoor pump stations in northern regions, high-temperature workshops), the -40°C to +70°C operating range of ABB UFC718AE01 is more advantageous, preventing module failure due to environmental factors.

7. Precautions

- Power Supply Specifications: Use only a standard 24V DC power supply; do not connect other voltage levels, as this may damage the internal circuitry of ABB UFC718AE01.

- Signal Calibration: Before commissioning, calibrate the sensor input signals using the ABB Control Builder M software to ensure the accuracy of collected data and avoid PID regulation failure due to calibration deviations.

- Hazardous Area Compliance: ABB UFC718AE01 is only suitable for ATEX Zone 2 hazardous areas; do not use it in higher-risk areas like Zone 1, as this violates safety regulations and may cause accidents such as explosions.

- Firmware Updates: Regularly obtain and update the firmware of ABB UFC718AE01 through official ABB channels to fix algorithm vulnerabilities and improve module compatibility and stability. Back up current configuration parameters before updating.

- Maintenance Operations: When replacing or overhauling ABB UFC718AE01, switch the process to manual control mode first to prevent production accidents or equipment damage caused by parameter out-of-control.

UFC718AE01

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922