Description

Product Overview and Introduction

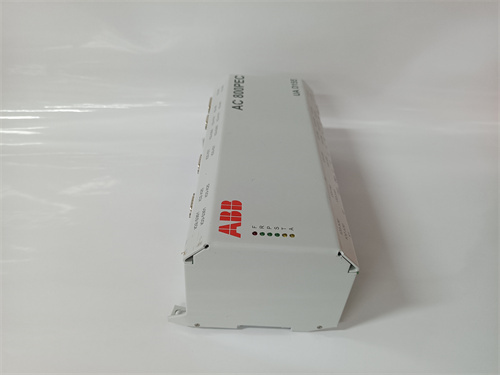

The ABB UAD155A0111 3BHE029110R0111 is a high-performance AC drive, specifically a member of the ABB ACS880 industrial drive series. This particular model is a multi-drive core unit, engineered to be the central power conversion module within a cabinet-built, high-power variable speed drive system. The ABB UAD155A0111 3BHE029110R0111 is designed for demanding applications that require precise control of motor speed and torque for large fans, pumps, compressors, and conveyors. It operates by converting incoming fixed-frequency AC power into a variable-frequency, variable-voltage output, enabling significant energy savings and process optimization.

Detailed Product Parameters and Specifications

This drive module is defined by its robust power and control specifications:

- Drive Platform: Part of the ABB ACS880 multi-drive series, designed for cabinet installation.

- Power Rating: A specific power rating defined by the model suffix, typically in the range of several hundred kilowatts (kW), suitable for high-power industrial motors.

- Input Supply: Designed for three-phase AC input, with standard voltage ratings such as 380-480V, 500-600V, or 660-690V AC, at 50/60 Hz.

- Output: Provides a variable frequency and voltage three-phase output to the motor, with a wide frequency control range (e.g., 0-500 Hz).

- Control Technology: Utilizes ABB’s Direct Torque Control (DTC) or scalar control modes, providing high dynamic performance, accurate speed control, and full motor torque at zero speed.

- Communication Interfaces: Equipped with multiple embedded fieldbus adapters (e.g., PROFIBUS DP, Modbus RTU, CANopen) and slots for optional communication modules (PROFINET, EtherNet/IP, EtherCAT).

- Protection Features: Comprehensive built-in protection for the drive and motor, including short circuit, earth fault, overvoltage, undervoltage, overload, and overtemperature protection.

- Cooling Method: Typically liquid-cooled or forced-air cooled, depending on the cabinet design and power level, to manage heat dissipation efficiently.

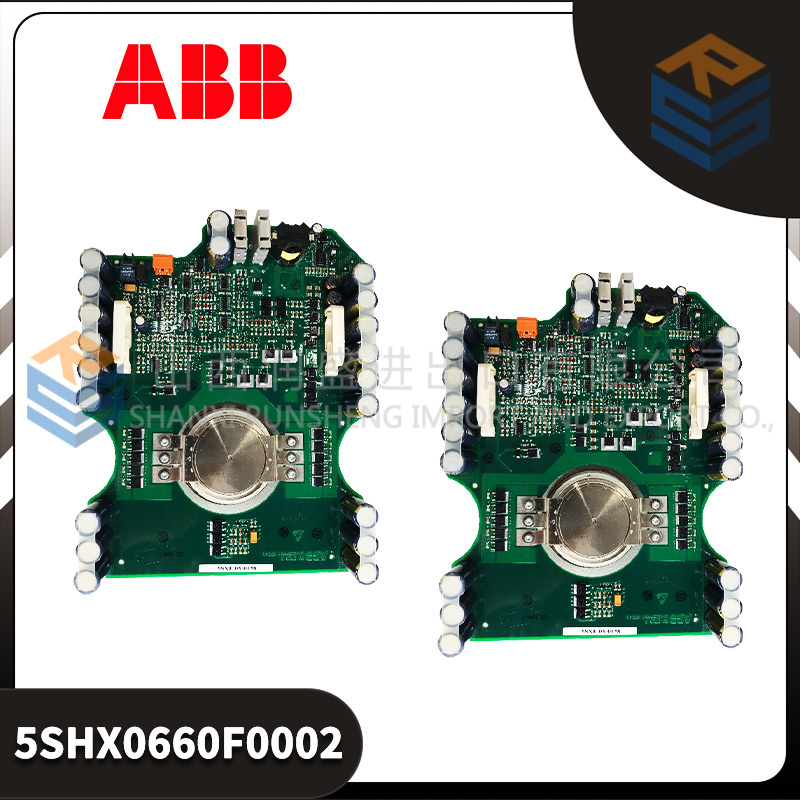

- Form Factor: A modular core unit designed to be installed alongside other components (input fuses/switches, line chokes, output filters) within a customer or system integrator’s cabinet.

Key Advantages and Distinctive Features

The ABB UAD155A0111 3BHE029110R0111 offers significant advantages for heavy-duty industrial control:

- High Energy Efficiency: Advanced power semiconductor technology and optimized control algorithms minimize losses, leading to substantial energy savings, especially in pump and fan applications.

- Superior Performance with DTC: ABB’s Direct Torque Control provides faster torque response and more accurate speed control than traditional V/Hz methods, improving process control and product quality.

- Unmatched Reliability: Built with industrial-grade components and designed for a long service life, ensuring maximum uptime in critical processes. The modular design also facilitates maintenance.

- Advanced Safety Features: Includes integrated Safe Torque Off (STO) functionality as standard (or as an option), providing a safety function that meets SIL 3/PLe standards, crucial for protecting personnel and equipment.

- Seamless System Integration: Extensive communication capabilities and compatibility with ABB’s Drive composer PC tool and higher-level control systems (like System 800xA) simplify engineering, diagnostics, and integration into plant-wide automation.

- Scalability and Flexibility: As part of the ACS880 multi-drive platform, it shares common engineering tools and spare parts with other drives in the range. The ABB UAD155A0111 3BHE029110R0111 can be customized with numerous options to perfectly match the application requirements.

Application Scenarios and Case Studies

This drive is applied in industries where controlling large motors is critical to efficiency and throughput:

- Mining & Minerals: Controlling the speed of grinding mills, conveyor belts, and large slurry pumps.

- Oil & Gas: Variable speed control for main line pipeline compressors, offshore water injection pumps, and gas turbine starters.

- Power Generation: Controlling boiler feed pumps, induced draft (ID) and forced draft (FD) fans, and cooling water pumps in thermal power plants.

- Water & Wastewater: Speed regulation for large raw water intake pumps, clean water booster pumps, and aeration blowers.

- Metals: Driving rolling mill main stands, run-out table rollers, and exhaust gas fans.

A typical application case is the retrofit of a fixed-speed induced draft fan in a power plant. Installing a system built around the ABB UAD155A0111 3BHE029110R0111 allowed the fan motor speed to be precisely matched to the boiler’s combustion air demand. This resulted in dramatic energy savings, reduced mechanical stress, and more stable boiler pressure control.

Comparison with Competing Products

When compared to similar high-power cabinet drives from competitors like Siemens (SINAMICS S120), Rockwell Automation (PowerFlex 755), or Danfoss (VACON 3000), the ABB UAD155A0111 3BHE029110R0111 is a leading solution:

- Control Performance: ABB’s DTC technology is often highlighted for its superior dynamic torque response, which can be a decisive factor in applications with rapidly changing loads or high precision requirements.

- Ecosystem Integration: For facilities using ABB PLCs (AC 800M) or the System 800xA DCS, the drive offers native integration benefits, including common engineering environment and advanced diagnostics.

- Global Service Network: ABB’s extensive global service and support infrastructure provides a strong advantage for multinational companies requiring consistent support.

Competitors may offer advantages in specific areas such as total cost of ownership for certain power ranges, different cabinet design philosophies, or specialized application-specific software features. The choice often involves a detailed technical and commercial evaluation.

Selection Guidelines and Important Considerations

Selecting and implementing this drive requires a comprehensive engineering approach:

- Accurate Motor and Load Data: Precise motor nameplate data (power, voltage, current, speed, cos phi) and load characteristics (torque vs. speed curve, inertia) are essential for proper drive sizing and tuning.

- Detailed Site Supply Conditions: Analyze the incoming power supply for voltage, frequency, short-circuit capacity, and harmonic distortion. This determines the need for optional input components like line reactors or harmonic filters.

- Control and Network Requirements: Define the required control signals (analog, digital) and select the appropriate fieldbus communication module for integration with the plant’s PLC/DCS.

- Cooling and Cabinet Design: The heat dissipation of the drive core unit is significant. The cabinet design must provide adequate cooling (liquid or forced air) as per the drive’s specifications and ambient conditions.

- Safety Integration: Plan the safety circuit design. If STO or other safety functions are required, ensure they are properly specified, wired, and validated according to relevant safety standards.

- Commissioning and Optimization: Use ABB’s Drive composer tool for commissioning. Critical steps include motor identification runs, application macro selection, and fine-tuning of speed/torque control loops. Always adhere to the installation and safety instructions in the hardware manual for the ABB UAD155A0111 3BHE029110R0111, available via the product link. Ensure all work is performed by qualified personnel with the drive completely isolated from power.

HIEE300698R0001 PLC

T9402 ICS PLC DCS

T9451 PLC

T9481 ICS

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922