Description

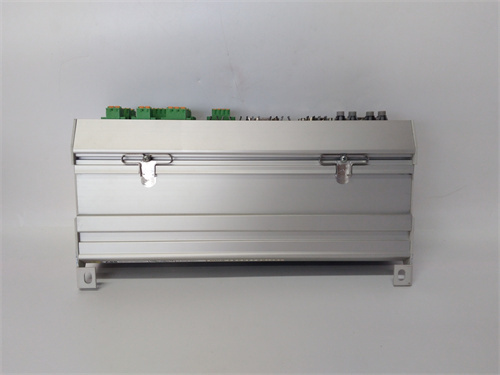

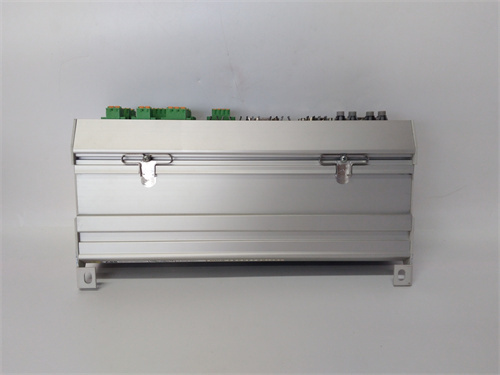

Product Description

The ABB UAD149A0011 is a precision analog input/output module designed for ABB’s Advant OCS (Open Control System) and MOD 300 distributed control systems, serving as a critical interface for process instrumentation in continuous industrial applications. This multifunction module provides eight configurable analog channels that can be individually programmed as either inputs or outputs, supporting 4–20 mA, 0–20 mA, and 0–10 V DC signals. The ABB UAD149A0011 represents the culmination of ABB’s field-proven Advant technology, engineered for reliability in harsh refinery, chemical, and power generation environments. Designed for mounting on Advant S100 I/O racks, this module communicates with Advant controllers via the S100 I/O bus, supporting both single and redundant configurations for critical process loops. The ABB UAD149A0011 incorporates comprehensive self-diagnostics and signal conditioning circuitry, eliminating external isolators and signal converters in most applications. Its rugged construction and conformal-coated circuit boards ensure reliable operation in industrial atmospheres containing airborne contaminants.

Product Parameters

- Model: ABB UAD149A0011

- Module Type: Analog Input/Output, Configurable

- Channel Count: 8, individually software-configurable

- Channel Modes: Input or output, per channel selection

- Input Signal Ranges: 4–20 mA, 0–20 mA, 0–10 V DC

- Output Signal Ranges: 4–20 mA, 0–20 mA, 0–10 V DC

- Resolution: 12-bit A/D and D/A conversion

- Accuracy: ±0.2% of span at 25°C, ±0.5% over temperature

- Update Rate: 20 ms for all channels (typical)

- Load Capability (Output): 0–600 Ω for current, > 2 kΩ for voltage

- Input Impedance: 250 Ω for current, > 1 MΩ for voltage

- Isolation: 500 V AC channel-to-ground, non-isolated between channels

- Indicators: Module status LED, communication LED, channel fault LEDs (grouped)

- Field Termination: 40-pin ELCO connector via transition cable to NTAI series termination blocks

- Power Consumption: 5 W from S100 I/O bus

- Operating Temperature: 0°C to 55°C

- Certifications: CE, UL, CSA, ATEX Zone 2, FM Class I Div 2, Marine (DNV, ABS)

Advantages and Features

The ABB UAD149A0011 delivers exceptional application flexibility through its per-channel configurability, enabling users to mix analog input and output signals within a single module without hardware modifications or external jumpers. This unique capability significantly reduces spare parts inventory requirements compared to fixed-function I/O modules, as a single ABB UAD149A0011 can serve multiple application requirements. The module’s software-configurable ranging eliminates the need for precision resistor networks or range cards, simplifying engineering and reducing commissioning time. Built-in signal conditioning provides cold junction compensation for thermocouple applications when used with appropriate external termination units. The ABB UAD149A0011 supports ABB’s redundant I/O architecture, where paired modules operate in hot-standby mode with automatic switchover upon primary module fault detection, ensuring uninterrupted control of critical process loops. Comprehensive self-diagnostics continuously monitor processor integrity, memory validation, and I/O circuit health, with any detected fault immediately reported to the controller and indicated via front panel LEDs. Non-volatile configuration storage eliminates battery dependency, ensuring immediate operation following power restoration without requiring reloading of configuration data. The ABB UAD149A0011‘s field-proven design has demonstrated mean time between failure exceeding 400,000 hours in continuous process applications.

Application Cases in Application Fields

- Refinery Fractionation Columns: Deployed on crude distillation unit sidecut strippers, the ABB UAD149A0011 configures four channels as 4–20 mA inputs for temperature transmitters and four channels as 4–20 mA outputs for reflux control valves, achieving complete loop control in a single I/O slot.

- Chemical Reactor Temperature Control: Installed in batch polymerization reactors, this module provides three RTD temperature inputs (via external converters) and five 4–20 mA outputs for cascade control of heating/cooling valves, with the ABB UAD149A0011‘s mixed I/O capability eliminating separate input and output modules.

- Power Plant Feedwater Control: Utilized in combined cycle heat recovery steam generators, the ABB UAD149A0011 monitors drum level pressure transmitters while simultaneously outputting setpoint signals to feedwater control valves, its fast update rate supporting 100 ms control loop execution.

- Pharmaceutical WFI Distribution: Applied in Water for Injection systems, six ABB UAD149A0011 input channels monitor conductivity, temperature, and flow transmitters while two output channels position recirculation flow control valves, maximizing I/O utilization in space-constrained cleanroom panels.

- Pulp and Paper Stock Preparation: Implemented in bleach plant chemical addition skids, the ABB UAD149A0011 provides mixed I/O for chlorine dioxide flow control loops, its per-channel configurability enabling last-minute process changes without hardware modification.

Comparison with Competing Products

| Feature | ABB UAD149A0011 | Honeywell 8C-PAIH51 | Siemens SM 334 | Emerson KJ3222X1 |

|---|---|---|---|---|

| Channel Count | 8 | 8 | 4 | 8 |

| I/O Flexibility | Per-channel configurable I/O | Input only | Mixed I/O (fixed ratio) | Input only |

| Signal Ranges | mA, V DC | mA, V, TC, RTD | mA, V | mA, V |

| Resolution | 12-bit | 16-bit | 12-bit | 16-bit |

| Isolation | 500 V channel/ground | 1500 V channel/channel | None | 500 V channel/ground |

| Hot-Swap Capable | Yes | Yes | Yes | Yes |

| System Compatibility | Advant, MOD 300 | Experion C300 | S7-300 | DeltaV |

| Typical Cost Position | Low-Mid | High | Low | Mid-High |

The ABB UAD149A0011 offers unique value among competitive products through its true per-channel I/O configurability, a feature absent from Honeywell and Emerson analog input modules which are input-only devices. While Siemens SM 334 provides mixed I/O capability, its 2-input/2-output fixed configuration (4 total channels) severely limits application flexibility compared to the ABB UAD149A0011‘s 8 individually configurable channels. The ABB UAD149A0011‘s 12-bit resolution, while modest by contemporary standards, remains entirely adequate for over 90% of continuous process control applications including pressure, flow, level, and temperature. For facilities maintaining Advant and MOD 300 infrastructure, the ABB UAD149A0011 represents the optimal solution for mixed analog I/O requirements, delivering exceptional flexibility at acquisition costs typically 40% lower than equivalent channel counts using separate input and output modules.

Selection Suggestions and Precautions

- System Compatibility Verification: Confirm that your Advant Controller 400 series or MOD 300 system version supports the ABB UAD149A0011; all Advant OCS with S100 I/O bus are compatible, but extremely early systems may require I/O bus firmware upgrades.

- Channel Configuration Requirements: The ABB UAD149A0011 requires software configuration of each channel as input or output using ABB’s Advant Engineering tools; configure all channels before commissioning as in-service changes may require module reset.

- Field Termination Selection: The ABB UAD149A0011 uses 40-pin ELCO connector; order appropriate transition cables (ABB NTAI05 for analog input, NTAO05 for analog output, or NTAI06 for mixed I/O applications) and termination blocks (NTAI02/NTAO02) for field wiring interface.

- Output Load Verification: When configuring ABB UAD149A0011 channels as 4–20 mA outputs, verify that connected load resistance does not exceed 600 Ω including wiring resistance; higher loads will cause output saturation and loss of control.

- Mixed I/O Isolation Considerations: The ABB UAD149A0011 provides channel-to-ground isolation but no channel-to-channel isolation; when mixing input and output signals on adjacent channels, verify that common mode voltages do not exceed module specifications.

- Thermocouple Applications: For thermocouple temperature measurement, the ABB UAD149A0011 requires external cold junction compensation via NTAI06 termination unit with integral CJC sensor; do not attempt direct thermocouple connection to standard NTAI02 blocks.

- Redundancy Configuration: For critical control loops requiring I/O redundancy, configure redundant ABB UAD149A0011 modules in adjacent I/O slots with field wiring split to both modules; verify that controller logic accommodates two separate analog input points for selection.

- Spare Parts Strategy: Given the ABB UAD149A0011‘s extensive installed base and ABB’s product lifecycle status for Advant platforms, maintain site-specific configured spare modules representing 5–10% of installed count; typical lead times for legacy modules extend to 10–14 weeks.

- Obsolescence Management: ABB has designated Advant technology as “Classic” status with committed support but limited new development; facilities planning 10+ year operating horizons should evaluate System 800xA migration paths while maintaining adequate ABB UAD149A0011 spares.

- Environmental Installation: Install the ABB UAD149A0011 in clean, climate-controlled environments; module accuracy specifications assume ambient temperature variation less than 10°C/hour and relative humidity below 85%.

- Calibration Verification: While the ABB UAD149A0011 does not require routine calibration, critical custody transfer or safety-related applications should perform annual accuracy verification using certified current/voltage sources with NIST-traceable certification.

- Connector Maintenance: ELCO connectors on the ABB UAD149A0011 are rated for 50 insertion cycles; mark installation date and track removal frequency, replacing transition cables when approaching cycle limits to prevent intermittent contact failures.

- Firmware Compatibility: Verify ABB UAD149A0011 firmware revision compatibility with your Advant controller firmware; modules manufactured after 2005 typically include revision 3.0 or later supporting enhanced diagnostics unavailable to earlier controller versions.

- Mixed I/O Documentation: Maintain clear documentation of ABB UAD149A0011 channel configuration (input vs output) for each module location; without visible hardware indicators, misdiagnosis of field wiring issues is common when channel configuration is not readily apparent.

TRICONEX 3664 PLC

TRIC0NEX 3700 PLC

TRICONEX 3701 PLC

TRIC0NEX 3703E PLC

TRIC0NEX 3708E PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922