Description

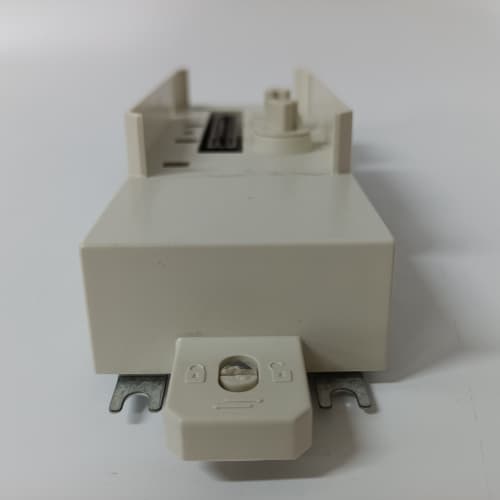

Product Description

The ABB TP858 is an advanced, high-performance industrial touchscreen panel PC from ABB’s CP600 series, designed to serve as a robust and flexible Human-Machine Interface (HMI) and operator workstation. This device integrates a powerful computing platform with a durable touchscreen display, functioning as a centralized visualization, control, and data management hub within automation systems. Its primary role is to provide operators with clear process graphics, real-time and historical trends, alarm management, and data logging capabilities, while also acting as an engineering station for configuration and maintenance tasks. The ABB TP858 is engineered for continuous operation in demanding industrial environments such as control rooms, factory floors, and hazardous areas (with appropriate certification). Its versatile connectivity allows seamless integration with a wide range of automation devices, including ABB AC 500 and AC 800M PLCs, third-party PLCs via OPC, and broader plant networks. Implementing the ABB TP858 delivers a powerful and reliable interface that enhances operational efficiency and situational awareness.

Product Parameters

- Device Family: ABB CP600 Panel PC Series.

- Device Type: Industrial Touchscreen Panel PC / HMI.

- Display: High-resolution TFT LCD touchscreen (size varies, e.g., 15-inch or larger).

- Processor: Multi-core industrial-grade processor (e.g., Intel Core i-series).

- Memory: Substantial RAM and solid-state drive (SSD) storage for operating system, applications, and historical data.

- Operating System: Typically Microsoft Windows 10/11 IoT Enterprise or a similar industrial OS.

- Communication Ports: Comprehensive set including:

- Multiple Ethernet ports (for plant network, device network).

- USB ports.

- Serial ports (RS-232/485).

- Options for fieldbus cards (PROFIBUS, PROFINET, etc.).

- HMI Software: Can run ABB’s System 800xA Operator Workplace, CP600 HMI software, or third-party SCADA/HMI packages like Wonderware or WinCC.

- Environmental Rating: High ingress protection (e.g., IP65 front), designed for washdown, dust, and harsh conditions.

- Mounting: Panel-mounted or arm-mounted for control room or machine integration.

Advantages and Features

- High Performance and Flexibility: The powerful PC architecture can run complex visualization software, multiple applications, and handle extensive data logging simultaneously, far exceeding the capabilities of traditional embedded HMIs.

- Durability and Reliability: Built with industrial-grade components and designed for 24/7 operation in challenging environments, ensuring long-term reliability and reduced downtime.

- Unified Visualization Platform: Capable of acting as a single window to the entire process, integrating data from multiple controllers and systems into one cohesive operator interface.

- Future-Proof and Scalable: The open PC platform allows for software upgrades, expansion of functionality, and adaptation to future technological changes more easily than fixed-hardware HMIs.

- Seamless ABB Ecosystem Integration: Offers optimized connectivity and driver support for ABB’s automation portfolio, simplifying engineering and ensuring high-performance data exchange.

Application Cases in Application Fields

- Central Control Room in a Water Treatment Plant: Serves as the primary operator station for supervising and controlling entire treatment processes, including pump stations, filtration, and chemical dosing.

- Manufacturing Cell Supervisor: Acts as a local supervisory station for a complex robotic assembly cell, providing detailed diagnostics, status, and manual override controls.

- Oil & Gas SCADA Operator Interface: Used as a ruggedized workstation in a field compressor station to monitor pressures, flows, and equipment health, and to execute remote commands.

- Food & Beverage Batch Processing: Provides recipe management, batch tracking, and equipment status visualization on the production floor.

Comparisons with Competing Products

- Vs. Siemens SIMATIC IPC series: Siemens offers similar industrial panel PCs. The ABB TP858 competes directly, with differentiation often in the pre-installed software ecosystem (System 800xA tools vs. Siemens WinCC/TIA Portal), specific ruggedization features, and brand preference within an existing plant architecture.

- Vs. Allen-Bradley PanelView Plus 7 Performance: The PanelView Plus is an embedded HMI terminal. The ABB TP858 is a full-fledged industrial PC, offering greater computing power, multi-tasking, and the ability to run full Windows applications, but at a higher cost and complexity.

- Vs. Standard Industrial PC with Separate Monitor: A rack-mount IPC and separate monitor offer similar compute power but lack the integrated, ruggedized design and optimized form factor of the purpose-built ABB TP858 panel PC.

Selection Suggestions and Precautions

- Define Primary Software Platform: Decide whether the ABB TP858 will run ABB’s native HMI software (e.g., for AC 800M), a third-party SCADA package, or both. This dictates the required software licenses, drivers, and configuration effort.

- Performance Specification Matching: Select the model with adequate processing power, memory, and storage based on the complexity of the visualization, the number of tags, historical data requirements, and any additional background applications.

- Environmental and Safety Certification: Verify that the device’s ingress protection (IP rating) and any hazardous area certifications (e.g., ATEX, IECEx) meet the requirements of its intended installation location.

- Lifecycle Management: As a Windows-based PC, plan for OS security updates, antivirus management, and eventual OS end-of-life. ABB typically provides long-term support and migration paths for their panel PC series.

- Integration and Networking: Plan the network architecture carefully. Utilizing separate network interfaces for plant IT communication and real-time device control (e.g., connecting directly to a PLC network) is a recommended best practice for security and performance.

ABB 3HAC031936-001 PLC

ABB 3HAC029924-001 PLC

3HAC029924-005 ABB PLC

ABB 3HAC17330-1 DCS

ABB DSQC505 PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922