Description

Product Overview and Introduction

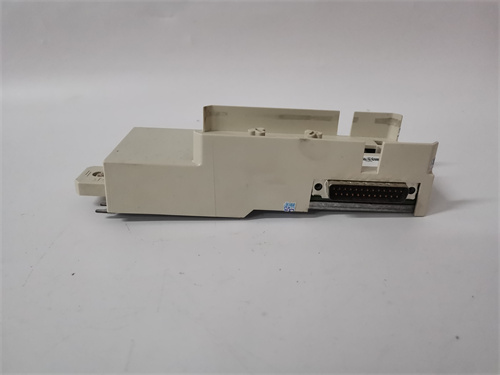

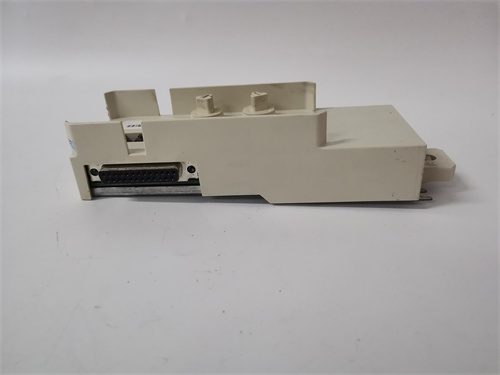

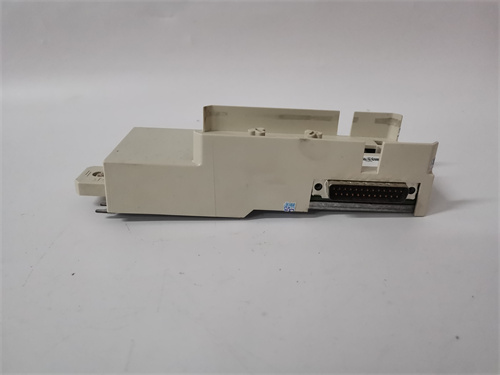

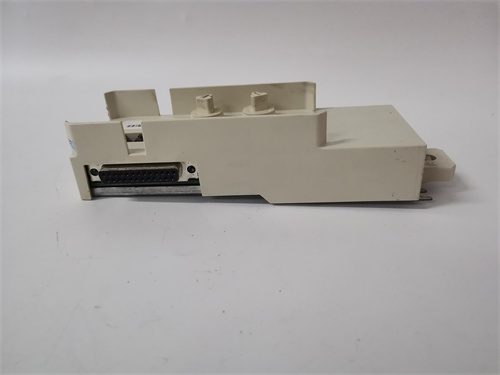

The ABB TP858 3BSE018138R1 is a high-performance Operator Panel or Display Terminal designed for the ABB Advant and MOD 300 distributed control systems (DCS). This unit serves as a critical human-machine interface (HMI), providing operators with a dedicated, robust window into the process for monitoring, control, and alarm management. The ABB TP858 3BSE018138R1 is engineered for continuous operation in demanding industrial control room environments, offering reliable visualization and interaction with the automation system through dynamic graphics, trends, and faceplates.

Detailed Product Parameters and Specifications

This operator terminal is defined by its display, connectivity, and functional specifications:

- Primary Function: Operator Workstation / Display Terminal for Advant/MOD 300 systems. It displays process graphics, alarms, trends, and logs, and allows for operator commands.

- Display: Features a monochrome or color CRT (Cathode Ray Tube) display with a specific diagonal size (e.g., 20-inch), known for its high contrast and readability in various lighting conditions.

- Resolution: Provides a specific display resolution (e.g., 1024×768 pixels) suitable for detailed process overview graphics.

- Input Method: Includes an integrated keyboard, typically with dedicated function keys, alphanumeric keys, and a trackball or joystick for cursor control and navigation.

- Communication Interface: Connects to the DCS via a proprietary high-speed network, such as ABB’s MasterBus 300, ensuring fast, deterministic update of process data.

- Processing Unit: Contains an internal processor and memory to handle graphic rendering and local data processing independently of the controller.

- Alarm Handling: Capable of receiving, displaying, and acknowledging system-wide alarms with audible and visual indicators.

- Redundancy Support: Often part of a system where multiple terminals provide backup, and they may connect to redundant communication networks.

- Power Supply: Requires a dedicated AC power source (e.g., 115/230V AC).

Key Advantages and Distinctive Features

The ABB TP858 3BSE018138R1 offers significant operational advantages for legacy DCS environments:

- Extreme Reliability and Longevity: Built to industrial standards for 24/7 operation, these terminals are known for exceptional mean time between failures (MTBF), providing years of dependable service in critical control rooms.

- Optimized for Control Room Use: The display technology, keyboard layout, and dedicated function keys are designed specifically for operator efficiency, reducing fatigue and error during extended monitoring sessions.

- Fast, Deterministic Data Update: Direct connection to the high-speed MasterBus ensures that displayed data is current and refreshes predictably, which is crucial during process upsets.

- Seamless System Integration: As a native ABB component, it integrates perfectly with the Advant/MOD 300 engineering and runtime environment, supporting all system features like faceplate navigation, group displays, and historical trending.

- Robust Construction: Designed to withstand the electrical noise and environmental conditions of an industrial setting. The ABB TP858 3BSE018138R1 is a cornerstone of the operator interface for many long-lifecycle process plants.

Application Scenarios and Case Studies

This operator panel is a central fixture in control rooms of large-scale continuous process industries:

- Pulp and Paper Mills: Used by operators to monitor and control the digesters, bleach plants, paper machines, and recovery boilers from a centralized control room.

- Chemical and Petrochemical Plants: Providing the interface for reactor control, distillation column operation, and utility management in facilities producing plastics, fertilizers, or base chemicals.

- Oil & Gas Refineries: Enabling operators to oversee crude units, catalytic crackers, and hydrotreaters, managing alarms and optimizing yields.

- Power Generation (Conventional): Serving as a unit operator’s station for controlling boiler-turbine-generator sets and balance-of-plant systems.

A typical application case is in an ammonia production plant. Multiple ABB TP858 3BSE018138R1 terminals are installed in the main control room, each assigned to a specific area (reforming, shift conversion, purification, synthesis). Operators use them to monitor pressures, temperatures, and flows, manipulate setpoints, and respond to alarms, ensuring safe and efficient production around the clock.

Comparison with Competing Products

In its era, the TP858 competed with proprietary operator stations from competitors like Honeywell (TDC 3000 GUS), Fisher-Rosemount (Provox/RS3 stations), and Foxboro (I/A Series workstations).

- System Cohesion and Performance: Its primary advantage was its tight, optimized integration with the ABB Advant controller architecture, offering excellent response times and a cohesive user experience designed for process engineers and operators.

- Hardware Reliability: Often benchmarked highly for its rugged hardware design and lower total cost of ownership due to long service life.

- Legacy System Role: Today, its comparison is against modern industrial PCs and thin clients running contemporary HMI software. The TP858‘s value is in its role as a sustainment part for existing systems, where it offers guaranteed compatibility and preserves operator familiarity.

Modern HMIs offer vastly superior graphics, web connectivity, remote access, and easier configuration, but require a migration of the entire control system platform.

Selection Guidelines and Important Considerations

Selecting, maintaining, or replacing this terminal today is primarily about legacy system support:

- Absolute System Compatibility: The ABB TP858 3BSE018138R1 is only compatible with specific versions of the ABB Advant or MOD 300 DCS. Verify compatibility with your system’s software and network configuration.

- Spare Parts as Lifecycle Management: This is a discontinued product. Sourcing is from specialized refurbishers or surplus. Procuring a tested spare unit is a critical strategy for mitigating the risk of failure.

- Display and Component Aging: CRT displays have a finite lifespan and can suffer from burn-in, dimming, or color degradation. Consider the condition of the display when acquiring a used unit. Keyboard wear is also common.

- Configuration and Database: The terminal’s functionality is entirely dependent on the DCS server’s configuration and graphics database. A replacement terminal must be loaded with the correct software version and configuration files.

- Installation and Power: Requires proper mounting in a control desk or console. Ensure a clean, stable AC power source with appropriate surge protection.

- Migration Planning: Given its age, developing a long-term migration plan to a modern HMI platform (like ABB Ability™ System 800xA) is essential for business continuity. For immediate support, always use the exact model number and consult the official hardware and service manual for the ABB TP858 3BSE018138R1, available via the product link. Operator training on the specific keyboard layout and navigation is necessary for new personnel.

1C31177G02 PLC

EMERSON 1C31177G03

1C31179G01 PLC EMERSON

1C31179G02 EMERSON

1C31181G01 EMERSON

1C31181G02 PLC EMERSON

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922