Description

Product Description

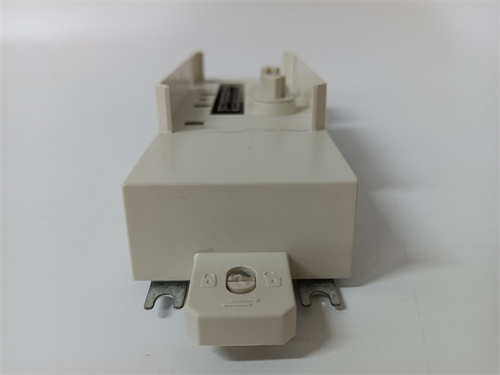

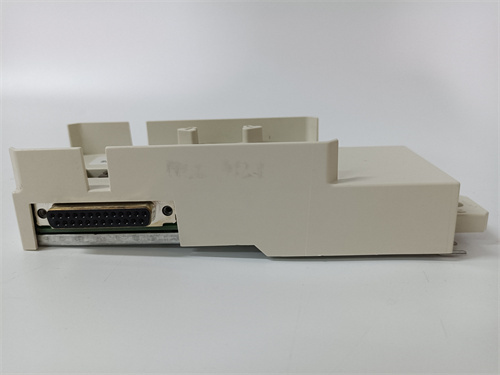

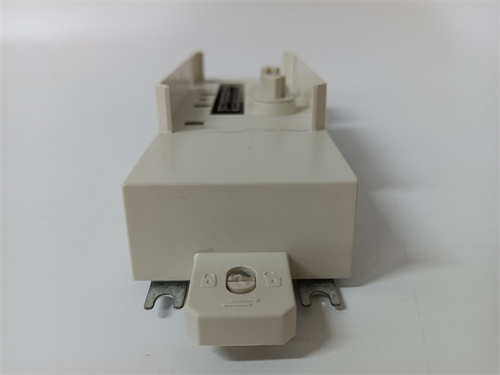

The ABB TP858 is a high-performance industrial operator panel, specifically a Touch Panel, designed for the ABB AC 500 PLC family and compatible with other automation systems. This device serves as a local Human-Machine Interface (HMI), providing operators with a graphical touchscreen to monitor processes, acknowledge alarms, adjust setpoints, and initiate control commands. The ABB TP858 features a robust, IP65-rated front panel, making it suitable for installation directly on machinery or in harsh industrial environments where dust and water exposure are concerns. It connects to the controller via standard industrial communication interfaces such as Ethernet or serial links. The intuitive design and durable construction of the ABB TP858 make it an ideal solution for providing direct operator access at the machine level. Integrating the ABB TP858 (https://www.example-link-abb-product.com) into an automation system enhances operational efficiency and local control capability. The clarity and responsiveness of the ABB TP858 interface facilitate effective interaction between personnel and the controlled process.

Product Parameters / Technical Specifications

-

Manufacturer: ABB

-

Product Family: AC 500 Operator Panels (Touch Panels)

-

Device Type: Industrial Touch Panel (HMI)

-

Model: TP858

-

Display: TFT color LCD with LED backlight.

-

Screen Size: Typically 8.4 inches diagonal, with a 4:3 aspect ratio.

-

Touch Technology: Resistive touchscreen.

-

Resolution: SVGA (800 x 600 pixels).

-

Processor & Memory: Integrated processor with dedicated memory for operating system and project runtime.

-

Communication Interfaces:

-

Ethernet: 10/100 Mbit for connection to PLCs (e.g., AC 500) and networks.

-

Serial Ports: COM1 (RS-232/485) and COM2 (RS-485) for legacy PLCs, printers, or other devices.

-

-

Protection Rating: IP65 (front panel) for protection against dust and water jets.

-

Operating System: Proprietary real-time operating system.

-

Programming Software: Configured using ABB’s Panel Builder 600 software.

-

Power Supply: 24V DC standard industrial supply.

-

Mounting: Panel-mounted (cut-out required) with mounting clamps.

Advantages and Key Features

-

Rugged Industrial Design: The IP65 rating of the ABB TP858 allows for installation in demanding environments directly on the factory floor, eliminating the need for a separate protective enclosure.

-

Excellent Visibility: The high-brightness SVGA display provides clear graphics and text, readable even in well-lit industrial settings.

-

Direct Machine-Level Interface: Puts control and monitoring directly where the action is, improving operator response times and situational awareness.

-

Easy Integration with ABB PLCs: Pre-configured drivers and communication settings for AC 500 and other ABB controllers streamline project development in Panel Builder 600.

-

Long-Term Availability: As part of a mature and widely adopted product family, it offers stability for long lifecycle machine designs.

Application Cases in Various Fields

-

Packaging Machinery: Mounted directly on a cartoner or filler for operators to start/stop the machine, select recipes, and monitor production counts.

-

Plastic Injection Molding: Used on the machine to display mold parameters, cycle times, and fault messages, and to manually control the mold open/close functions.

-

Material Handling: Installed on a conveyor control station to display system status, belt speeds, and allow manual control of diverters.

-

Water Treatment Skids: Providing a local interface for skid-mounted equipment to display pressures, flows, and tank levels, and to initiate backwash sequences.

-

Food & Beverage Processing: Serving as the main operator station on a cooker or mixer for temperature control and batch step monitoring.

Comparison with Competing Products

The ABB TP858 competes with other mid-sized industrial HMIs such as the Siemens SIMATIC HMI TP700 Comfort, the Schneider Electric Magelis GXO, and the Rockwell Automation PanelView Plus 7. Its key advantages are its rugged IP65 front-panel design without needing an additional bezel, its strong native integration with the ABB AC 500 ecosystem, and its competitive price-to-performance ratio. Compared to larger graphical stations, it offers a more compact and cost-effective solution for dedicated machine control. Compared to basic text panels, it provides far superior visualization and interaction.

Selection Suggestions and Precautions

-

Selection Advice: Select the ABB TP858 for new machine builds or upgrades requiring a durable, panel-mounted touchscreen HMI with direct connectivity to an ABB AC 500 PLC (or other supported controller via standard protocols). It is ideal for applications where the HMI will be exposed to washdowns, dust, or general industrial grime. Ensure the screen size and resolution are sufficient for the planned graphics and data display.

-

Precautions:

-

Panel Cut-out Dimensions: Carefully follow the mechanical drawing for the panel cut-out. An improper cut-out can compromise the IP65 seal.

-

Communication Planning: Determine the communication path (Ethernet or serial) to the PLC during the design phase. Have the correct cables and connectors on hand.

-

Project Development Software: You must use ABB’s Panel Builder 600 software to create the HMI application. Ensure you have access to the correct version.

-

Power Supply Quality: Use a clean, well-regulated 24V DC power supply. Voltage spikes or noise can cause the panel to reset unexpectedly.

-

Backup and Documentation: Always keep a backup of the Panel Builder 600 project file (.pbr). Document the communication parameters (IP address, baud rate) used in the project.

-

ABB NTAC-01 dcs

NAIO-02 ABB

ABB AI815

ABB A0815 PLC

ABB DSTD108P DCS

IMCIS02 ABB PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922