Description

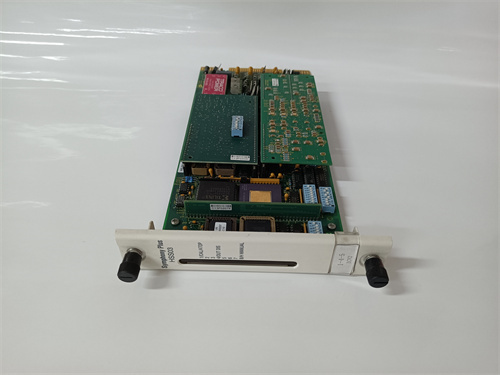

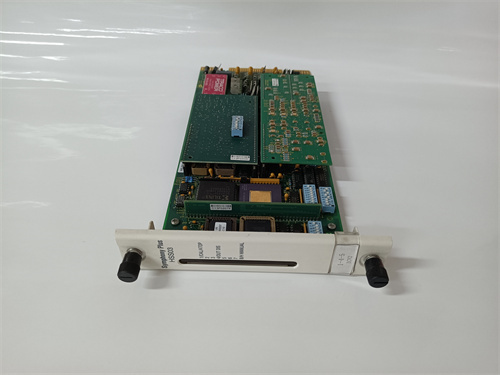

Product Description

The ABB SPNPM22 is a versatile and configurable digital input/output (DI/DO) module designed for the ABB AC 500 PLC and AC 500-eCo controller families. This module serves as a flexible interface for connecting both digital sensors and actuators to the programmable logic controller. A key feature of the ABB SPNPM22 is its configurability; each of its 16 channels can be individually programmed via software to function as either a digital input (to read signals from devices like push buttons and limit switches) or a digital output (to control devices like solenoid valves and indicator lamps). This flexibility makes the ABB SPNPM22 an excellent choice for applications where the exact mix of inputs and outputs may not be known during the initial design phase or may need to change over time. It mounts directly onto the PLC rack and communicates over the system backplane. Integrating the ABB SPNPM22 (https://www.example-link-abb-product.com) into an AC 500 system provides a high-density, adaptable solution for discrete control tasks. The design and software-defined functionality of the ABB SPNPM22 help optimize cabinet space and simplify inventory management.

Product Parameters / Technical Specifications

- Manufacturer: ABB

- Product Family: AC 500 / AC 500-eCo PLC I/O

- Module Type: Configurable 16-Channel Digital Input/Output Module

- Model: SPNPM22

- Number of Channels: 16

- Channel Configuration: Each channel is individually software-configurable as:

- Digital Input (DI): 24V DC, sinking or sourcing.

- Digital Output (DO): 24V DC, transistor output (typically 0.5A per channel).

- Isolation: Channels are isolated in groups (e.g., 8 points per common).

- Diagnostics: Includes diagnostics for short-circuit on outputs and wire-break on inputs.

- Status Indication: LED per channel for state indication (On/Off).

- Voltage Levels: Operates with a 24V DC field supply.

- Update Time: Fast scanning suitable for standard discrete control.

- Communication: Interfaces with the PLC CPU via the system backplane.

- Configuration: Fully configured within ABB’s Automation Builder engineering software.

- Mounting: Mounts on a standard AC 500 I/O base unit.

Advantages and Key Features

- Maximum Flexibility: The standout feature of the ABB SPNPM22 is its per-channel configurability, allowing engineers to adapt the I/O mix to exact application requirements without changing hardware.

- High Density: Provides 16 configurable points in a single module slot, offering excellent space efficiency in control cabinets.

- Reduced Spare Parts Inventory: A single module type can serve as a spare for various fixed DI or DO modules, simplifying logistics and reducing costs.

- Software-Defined Functionality: Changes to I/O assignment are made in software, enabling quick adaptations during commissioning or machine modifications.

- Seamless AC 500 Integration: Fully supported within the ABB Automation Builder environment, allowing for easy configuration, monitoring, and troubleshooting.

Application Cases in Various Fields

- Packaging Machinery: Interfacing with a complex array of sensors (photo-eyes, product detectors) and actuators (solenoids, valves) on a machine where the I/O mix is subject to design changes.

- Material Handling Systems: Controlling and monitoring sections of a conveyor system, where some points need to be inputs (sensor status) and others outputs (motor starter commands).

- Process Skid Control: Providing I/O for vendor-packaged equipment where the final interface requirements with the plant may vary.

- Small to Medium Automation Cells: Serving as the primary discrete I/O interface for a robotic workcell or assembly station.

- Building Automation: Managing a mix of occupancy sensors, light switches (inputs), and relay controls for lighting and fans (outputs).

Comparison with Competing Products

The ABB SPNPM22 competes with other configurable digital I/O modules from PLC manufacturers, such as the Siemens ET 200SP DIQ/DOQ module or the Schneider Electric BMX DDI/DDO modules for Modicon M340. Its primary advantage is its deep integration and single-channel granularity within the ABB AC 500 ecosystem. Compared to using separate, fixed 16-channel DI and DO modules, the SPNPM22 offers superior space savings and flexibility for uncertain or evolving applications. For projects with a known, fixed number of pure inputs and outputs, dedicated modules might be more cost-effective.

Selection Suggestions and Precautions

- Selection Advice: Choose the ABB SPNPM22 for AC 500 projects where flexibility is paramount, such as in prototype machines, skid-mounted equipment, or applications where I/O requirements are likely to evolve. It is ideal for optimizing a single module slot when you need a balanced but undetermined mix of DI and DO points. For applications with a very high, known count of purely inputs or outputs, dedicated modules may be preferable.

- Precautions:

- Configuration Planning: While flexible, the I/O configuration must be carefully planned and documented in the software. The physical wiring must match the software configuration for each channel (e.g., an output channel cannot have a sensor wired to it).

- Load Ratings: When configured as an output, respect the per-channel and total group current ratings. Use external suppression for inductive loads (relays, solenoids).

- Wiring and Commons: Adhere to the common grouping for isolation. All channels within a group share a common terminal. Mis-wiring across commons can cause malfunction.

- Power Budget: Ensure the PLC power supply has sufficient capacity to handle the total load, especially when many channels are configured as outputs.

- Software Control: The module’s functionality is entirely defined by the software configuration. Always back up the Automation Builder project. Replacing the module requires the configuration to be downloaded to the CPU.

PE1364B

ABB PCU-03

DSTA160 ABB

ABB NTAC-02 dcs

57520001-Z/1

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922