Description

Product Overview and Introduction

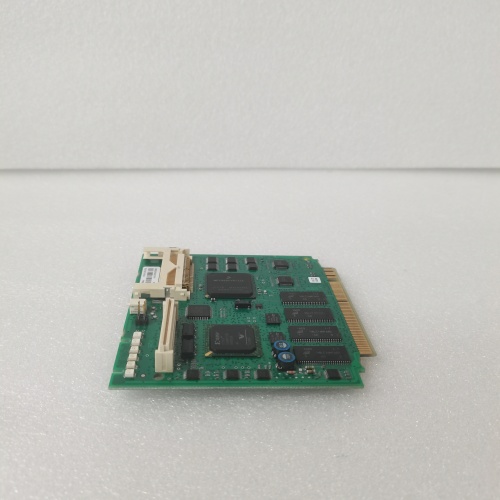

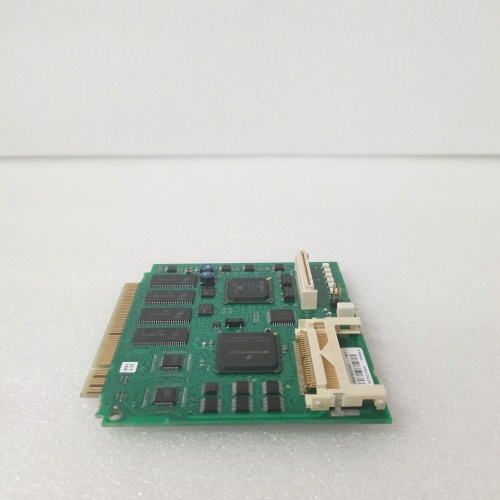

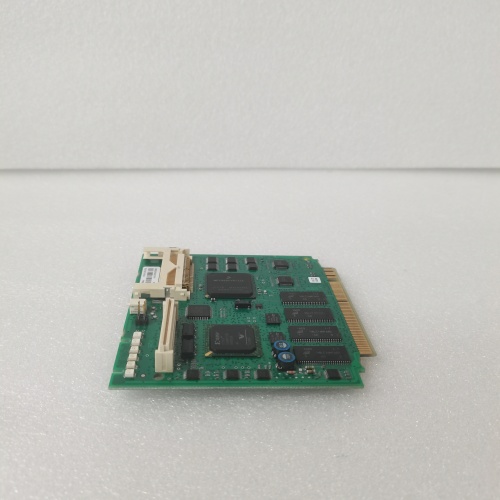

The ABB PM866-2 3BSE050201R1 is a high-performance, dual processor Controller Unit (CPU) for the ABB AC 800M series, serving as the central brain within the ABB Ability™ System 800xA distributed control system (DCS). This advanced controller is engineered for the most demanding process automation applications, delivering exceptional computational power, reliability, and deterministic performance for complex control strategies in industries like oil & gas, power generation, chemical, and pharmaceuticals. The ABB PM866-2 3BSE050201R1 is a key enabler for implementing advanced process optimization, batch management, and safety instrumented functions.

Detailed Product Parameters and Specifications

This controller’s performance is defined by its robust hardware and functional architecture:

- Processor Architecture: Features a powerful, dual-core CPU specifically designed for deterministic real-time industrial control. The dual-core design allows for separation of critical control tasks (e.g., a dedicated core for safety functions).

- Memory: Equipped with significant volatile (RAM) and non-volatile (Flash) memory for storing the operating system, user application programs, and historical data.

- Execution Performance: Extremely fast and deterministic scan times, capable of handling tens of thousands of I/O points and executing complex function blocks (PIDs, advanced control) within a tight, predictable cycle.

- Redundancy: Designed for high-availability configurations. Two PM866-2 controllers can be configured in a redundant (hot standby) pair, where the standby unit synchronizes memory and seamlessly takes over control in the event of a primary unit failure with minimal switchover time.

- Communication Interfaces: Includes multiple, often redundant, communication ports:

- Control Network (CNet): For peer-to-peer communication with other controllers and connectivity to operator stations.

- I/O Networks: Interfaces for connecting to ABB S800 I/O (via CI854 modules for Profibus DP, CI871 for MasterBus 300) and other fieldbus systems.

- Engineering/Maintenance Port: For configuration and diagnostics.

- Safety Capability: Certain variants can be certified for Safety Instrumented System (SIS) applications, meeting standards like IEC 61508 SIL 3.

- Power Supply: Requires a stable 24 V DC power source, typically from redundant power supplies in the controller rack.

- Operating System: Runs a proprietary, hard real-time operating system optimized for reliability and determinism.

Key Advantages and Distinctive Features

The ABB PM866-2 3BSE050201R1 provides critical system-level advantages:

- Unmatched Processing Power and Determinism: Its dual-core architecture ensures the capacity to execute even the most complex control algorithms (e.g., model predictive control) with consistent, millisecond-level scan times, which is essential for process quality and stability.

- Highest Level of Availability: The robust hardware redundancy support virtually eliminates the risk of unscheduled downtime due to controller failure, a critical factor for continuous processes with high revenue impact.

- Seamless 800xA Integration: As the core control engine of System 800xA, it offers perfect synergy with the engineering, visualization, and asset management tools, providing a unified environment for the entire plant lifecycle.

- Future-Proof Scalability: Its high performance headroom allows for future expansion of I/O counts and application complexity without needing a controller upgrade, protecting the automation investment.

- Consolidated Control and Safety: In appropriate configurations, it can integrate basic process control (BPCS) and safety instrumented functions (SIS) into a single hardware platform, simplifying engineering and maintenance while meeting stringent safety standards.

- Global Support and Proven Reliability: Backed by ABB’s global service network and with a vast installed base, the ABB PM866-2 3BSE050201R1 is a trusted and proven choice for mission-critical automation.

Application Scenarios and Case Studies

This controller is deployed as the main process unit controller in large, complex industrial facilities:

- LNG Liquefaction Trains: Controlling the complex, integrated cryogenic processes of gas pre-treatment, liquefaction, and nitrogen rejection.

- Refinery Process Units: Acting as the main DCS controller for fluid catalytic cracking (FCC) units, hydrocrackers, or large crude distillation columns.

- Power Plant Wide Control: Coordinating the entire boiler-turbine-generator (BTG) island and balance-of-plant systems in a thermal power station.

- Pharmaceutical Batch Production: Executing complex ISA-88 batch recipes for bioreactors and purification skids with rigorous audit trails.

- Large Pulp & Paper Mills: Managing the integrated control from digester to paper machine and recovery boiler.

A typical application case is a large ethylene cracker. Multiple redundant ABB PM866-2 3BSE050201R1 controllers are deployed. One pair manages the cracking furnace section with complex temperature and flow control, another pair controls the hot section and quench tower, and a third manages the cold section and compression. Their peer-to-peer communication allows for coordinated plant-wide control, while their redundancy ensures continuous operation of this high-value, continuous process.

Comparison with Competing Products

When compared to top-tier process controllers from competitors like Emerson (DeltaV MD Controller), Siemens (SIMATIC PCS 7 AS-410), or Honeywell (Experion C300), the ABB PM866-2 3BSE050201R1 stands as a leading solution:

- Performance in Complex Algorithm Execution: Often noted for its ability to handle computationally intensive custom control algorithms and large-scale model-based optimization packages efficiently.

- Tightness of 800xA Integration: The integration is more than just communication; the controller is a fundamental object within the 800xA aspect-oriented database, offering superior engineering and diagnostic cohesion.

- Redundancy Mechanism: ABB’s controller redundancy is renowned for its fast, bumpless switchover and robust synchronization, which is a key decision factor for many users.

Competitors may offer advantages in specific areas such as embedded wireless integration, different form factors, or specific industry library content. The choice often involves a detailed evaluation of the total system architecture and specific application needs.

Selection Guidelines and Important Considerations

Selecting and implementing this high-end controller is a significant engineering undertaking:

- System Architecture and Sizing: The ABB PM866-2 3BSE050201R1 must be part of a meticulously planned 800xA system. Perform detailed I/O counts, function block estimates, and performance modeling to ensure the controller is appropriately sized. Consider future expansion.

- Redundancy is Standard for Critical Processes: For any application where unplanned shutdown is costly or hazardous, a redundant controller pair is considered mandatory. Budget and design for this from the outset.

- Network Design: Plan the Control Network (CNet) and I/O network topology carefully. Redundant networks are standard for high-availability systems. The controller’s communication modules (CI cards) must be selected accordingly.

- Software and Licensing: Ensure you have the correct versions of System 800xA software, controller firmware, and the necessary runtime licenses (for redundancy, advanced libraries, etc.).

- Safety Application Validation: If used for safety functions (SIL), the entire system—including hardware, software, and engineering process—must be designed, validated, and documented according to the relevant safety standards. This is a specialized activity.

- Expert Implementation and Cybersecurity: Configuration requires deep expertise with Control Builder M. Partner with certified system integrators. Cybersecurity must be integral: implement secure boot, role-based access control, network segmentation, and patch management. Always use the official hardware manual and configuration guide for the ABB PM866-2 3BSE050201R1, accessible via the product link. Rigorous Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT) are essential.

1C31205G01 EMERSON

1C31206G01 EMERSON

EMERSON 1C31224G02

1C31227G02 PLC EMERSON

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922