Description

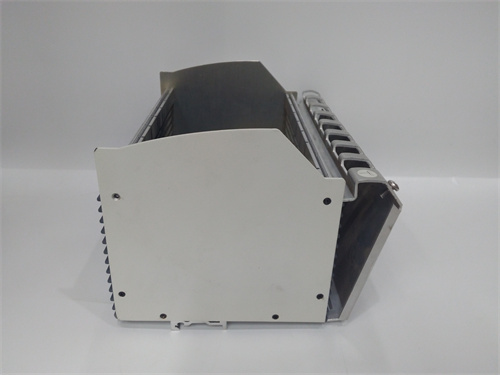

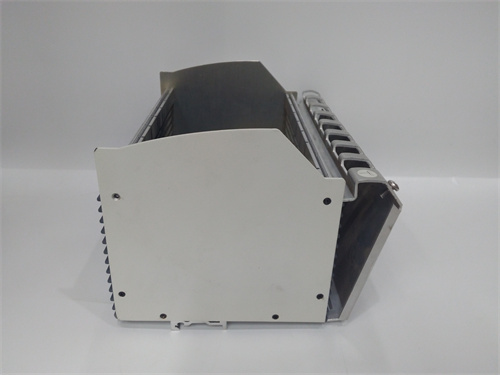

ABB PM803F: High-Performance Process Controller for AC 800M

Product Description

The ABB PM803F is a high-performance, safety-certified controller within the ABB AC 800M family, designed specifically for process automation and safety applications. This controller integrates both standard control and safety functionality into a single hardware unit, making it a key component for implementing Safety Instrumented Systems (SIS) and Basic Process Control Systems (BPCS) in an integrated architecture. The ABB PM803F executes logic with a fast and deterministic scan time, managing complex regulatory control, sequencing, and safety interlocks simultaneously. It is engineered for high availability and reliability in critical process environments, supporting hot-swap and redundant configurations. As part of ABB’s System 800xA, the ABB PM803F enables a unified engineering and operational environment for both process and safety control.

Product Parameters

- Product Type: High-Integrity Process and Safety Controller

- Manufacturer: ABB

- Part Number: PM803F

- Controller Family: AC 800M

- Safety Certification: TÜV-certified for use in Safety Integrity Level (SIL) 3 applications per IEC 61508.

- Memory: Substantial user memory for application logic and data.

- Processing Power: High-performance processor for demanding control tasks.

- Communication Ports: Multiple ports including Ethernet (for 800xA connectivity, peer-to-peer, and OPC), serial, and potentially fieldbus master interfaces (via communication modules).

- Redundancy: Supports CPU redundancy (with a paired PM803F) for high-availability applications.

- I/O Compatibility: Connects to ABB S800 I/O (High Integrity and standard) and other fieldbus networks via communication modules.

Advantages and Features

The primary advantage of the ABB PM803F is its dual capability as a high-performance process controller and a certified safety controller, which can reduce system complexity, engineering costs, and footprint compared to using separate systems. It features a powerful processor capable of handling large numbers of I/O points and complex control algorithms. The controller offers excellent integration within System 800xA, allowing for shared engineering (Control Builder M), operator stations, and historical data. Safety and standard applications run in isolated partitions on the same hardware, ensuring separation while simplifying maintenance. The ABB PM803F supports advanced diagnostics and condition monitoring, contributing to overall plant asset management and reliability.

Application Cases in Various Fields

This controller is ideal for integrated control and safety applications. In Oil & Gas, the ABB PM803F can manage the basic process control of a separation unit while simultaneously executing the Safety Instrumented Functions (SIFs) for Emergency Shutdown (ESD). Within Chemical and Petrochemical plants, it controls reactor temperature and pressure loops (BPCS) and runs the associated safety interlocks (SIS) on the same hardware. For Pharmaceutical manufacturing, it ensures precise batch control while managing critical safety interlocks for personnel and product protection. It is also used in Power Generation for burner management and auxiliary system control.

Comparisons with Competing Products

The ABB PM803F competes with other integrated process/safety controllers like the Emerson DeltaV SIS with CHARM I/O or the Siemens SIMATIC PCS 7 with F-CPU. Compared to using a separate, dedicated safety PLC (like a Triconex or HIMA system) alongside a standard DCS/PLC, the integrated ABB PM803F offers potential savings in hardware, engineering, and lifecycle costs, while maintaining the necessary safety certification. Its key differentiator is its deep and seamless integration into the ABB System 800xA, which is one of the leading DCS platforms for large process industries, providing a unified environment from sensor to boardroom.

Selection Suggestions and Precautions

- Safety Lifecycle Compliance: Implementing safety functions with the ABB PM803F requires strict adherence to the IEC 61511 safety lifecycle. This includes a Safety Requirements Specification (SRS), thorough validation testing, and formal functional safety management. It is not merely a programming task.

- Engineering Tool Expertise: Configuration requires ABB’s Control Builder M engineering software with specific knowledge for partitioning the application into standard and safety-related sections. Personnel should have appropriate training for safety system engineering.

- I/O Selection: Safety functions must use certified safety I/O modules (e.g., S800 I/O High Integrity). Do not mix standard and safety I/O on the same function. The ABB PM803F can communicate with both, but the physical I/O hardware must be appropriate for the safety integrity level.

- Redundancy Requirements: For high-availability or high-safety applications, evaluate the need for controller redundancy. The ABB PM803F supports this, but it requires a specific hardware configuration and software setup.

- Testing and Documentation: Safety applications require rigorous testing and comprehensive documentation. Changes to the safety logic in the ABB PM803F must go through a formal Management of Change (MOC) process. Regular proof testing of the entire safety loop is mandatory to maintain the SIL rating.

9905-678 PLC

9905-699 PLC

9905-703 DCS

9905-707 PLC

9905-708 PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922