Description

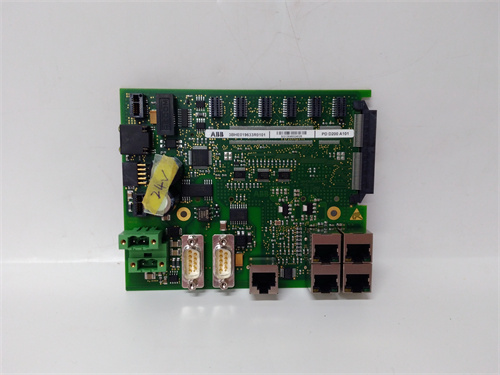

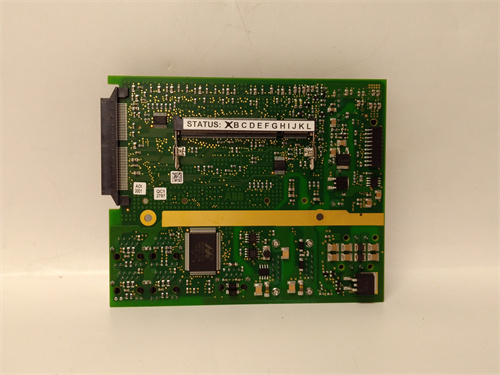

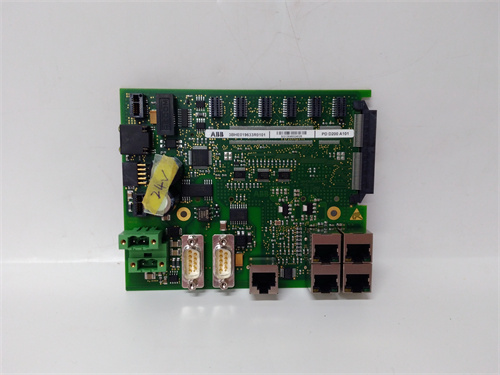

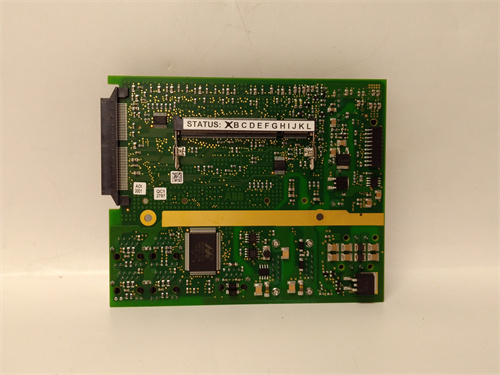

Product Description

The ABB PDD200A101 is a dedicated, high-capacity DC power supply module designed for use within ABB’s industrial control and automation systems, most notably as part of the S800 I/O station or other cabinet-based distributed I/O solutions. This module functions as the central power hub for a local cluster of I/O modules, converting the incoming AC mains or a higher-voltage DC supply into the precisely regulated, low-voltage DC power required for the operation of digital and analog I/O circuits. The primary function of the ABB PDD200A101 is to ensure that all connected S800 I/O modules receive clean, stable, and protected 24 VDC power, which is critical for accurate signal measurement and reliable output switching. By implementing this power supply, system designers create a robust and independent power domain for the I/O station, isolating it from noise and fluctuations that may exist on the plant-wide DC bus. The ABB PDD200A101 is a key component in building reliable, modular, and high-performance distributed I/O architectures.

Technical Parameters and Features

- Device Type: DC/DC or AC/DC Power Supply Module for distributed I/O stations.

- Input Voltage: The “PDD200A” suggests a specific input range. Common configurations include:

- 24/48/110 VDC Input: For systems with a central DC battery plant.

- 115/230 VAC Input: For direct AC connection.

- The “101” suffix likely specifies the exact input voltage variant (e.g., 24 VDC input).

- Output Specifications:

- Output Voltage: 24 VDC, the standard for S800 I/O module logic and field power.

- Output Current/Power: The “200” indicates a significant power rating, typically 200 Watts or a corresponding high current output (e.g., 8.5A at 24V), sufficient to power a fully loaded S800 station with multiple modules.

- Protection Features: Includes standard industrial protections such as overload protection, short-circuit protection, and overvoltage protection to safeguard both the supply and the connected I/O modules.

- Efficiency: High-efficiency design to minimize heat generation within the control cabinet.

- Cooling: May be convection-cooled or include an internal fan, depending on the power rating and model.

- Mounting: Designed for DIN-rail mounting (35mm) within the I/O station cabinet.

- Termination: Screw terminal blocks for secure power input and output connections.

- Status Indication: LED indicators for input power (ON) and output status (OK/Fault).

- Redundancy Option: Can often be configured in parallel (N+1) redundant setups for high-availability applications by using diode modules (e.g., ABB DIO01).

Advantages and Key Features

- High Power Capacity for Demanding I/O Stations: The 200W rating of the ABB PDD200A101 allows it to support extensive S800 I/O configurations, including power-hungry analog and communication modules, without requiring an external supplementary supply.

- Optimized for S800 I/O Ecosystem: This power supply is specifically tested and validated for use with ABB S800 I/O modules. It ensures correct start-up sequencing, voltage tolerances, and noise immunity required for the precise operation of the I/O system.

- Robust Electrical Performance: Provides excellent line and load regulation, ensuring a stable 24VDC output even with fluctuations in the input source or varying I/O load conditions. This stability is crucial for analog measurement accuracy.

- Simplified Cabinet Design: Its DIN-rail mounting and integrated design streamline cabinet layout, reducing the need for separate power conversion stages and simplifying wiring compared to using multiple smaller supplies.

- Supports High Availability Architectures: The ability to be used in redundant parallel configurations makes the PDD200A101 suitable for critical process applications where I/O station power loss cannot be tolerated.

Application Case Studies in Various Fields

- Pharmaceutical Batch Plant (S800 I/O Station): A ABB PDD200A101 power supply in a remote cabinet powers an S800 station that interfaces with dozens of temperature sensors (RTDs), pressure transmitters, and control valves for a reactor. Its clean power ensures measurement integrity for recipe control.

- Power Plant Turbine Auxiliary Systems: Used in a distributed I/O cabinet near the turbine deck. It powers I/O modules that monitor bearing temperatures, vibration, and lube oil pressure, feeding data back to the main DCS via a fieldbus connection.

- Automotive Paint Shop: In a harsh environment, a cabinet with this supply powers I/O modules controlling robotic paint valves and solvent concentration sensors. The supply’s robustness ensures reliability despite electrical noise from large paint circulating pumps.

- Water Distribution SCADA: Installed in a remote pumping station RTU cabinet, the PDD200A101 powers the local S800 I/O that collects flow, pressure, and tank level data for telemetry to the central SCADA master.

Comparison with Competing Products

Compared to using a generic 24VDC DIN-rail power supply or power supplies from other PLC vendors, the ABB PDD200A101 offers system-specific benefits:

- Validated System Component vs. Generic Part: While a generic 200W supply might physically work, the PDD200A101 is validated as part of the S800 system. ABB ensures its performance under all load conditions typical of an I/O station, including inrush currents during module insertion, which a generic supply may not handle gracefully.

- Seamless Integration with Redundancy Kits: ABB provides dedicated redundancy diode modules (DIO01) designed to work with supplies like the PDD200A101 for creating N+1 systems. Implementing redundancy with generic supplies requires custom engineering and external diodes, adding complexity and potential points of failure.

- Predictable Performance and Support: As an OEM part, its specifications and behavior are guaranteed. Troubleshooting power issues within an ABB system is straightforward when using the specified component, and support is readily available.

Selection Advice and Important Notes

- Verify Input Voltage Requirement: The suffix “101” is critical. It defines the input voltage (e.g., 24VDC, 110VAC). Ordering the wrong input variant will render the PDD200A101 module unusable. Always confirm the input voltage of your cabinet’s source.

- Perform a Detailed Load Calculation: Calculate the total 24VDC current consumption of all S800 I/O modules, communication interfaces, and any ancillary devices in the station. Ensure the total is less than the supply’s rated current, maintaining a 20-30% safety margin for reliability and future expansion.

- Implement Proper Fusing and Protection: The power supply’s input should be protected by a correctly rated fuse or circuit breaker according to the local electrical code and the supply’s datasheet. The output may also require fusing for individual I/O module groups.

- Ensure Adequate Cooling and Derating: Install the supply with proper clearance for airflow. Note that the maximum output current is derated at high ambient temperatures; consult the derating curve in the datasheet to ensure adequate capacity in hot environments.

- Use for Station Power, Not Field Power: The ABB PDD200A101 is intended to power the I/O module electronics. It is generally not recommended to also power field devices (sensors, actuators) from the same supply, as faults or noise from the field could disrupt the entire I/O station. Use separate supplies for field power.

745-W2-P5-G5-HI-A-R-T PLC

3HAC7998-2

3HAC026787-002 PLC

3HAC025465-011 PLC

6SE7015-OEP60-Z/G91 PLC

GALILDMC-3425 PLC

1336F-BRF100-AA-EN

1756-PB75R PLC

1900 65A-01-01-01-00-01 PLC

NZM12-800 PLC

MVME3100-1152 PLC

DO880

330850-90-05 PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922