Description

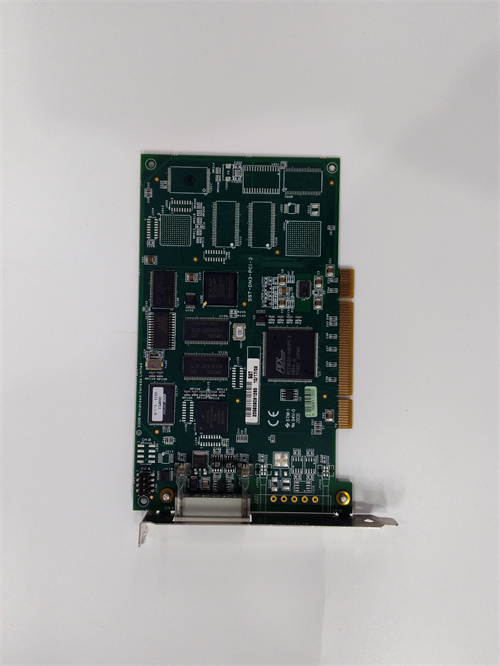

ABB DSQC602 is a high‑performance digital I/O and drive interface module for ABB IRC5 robot controllers, dedicated to handling real‑time I/O signals and precise servo drive control in industrial robotics applications like automotive manufacturing, electronics assembly, and material handling. ABB DSQC602 integrates 16 digital inputs and 16 digital outputs with 24 VDC compatibility, supporting fast signal response (≤1 ms) for high‑speed robot motion control. ABB DSQC602 uses Profibus‑DP and DeviceNet protocols for seamless data exchange with IRC5 controllers, enabling coordinated operation of robot axes and peripheral equipment. ABB DSQC602 features redundant power inputs and built‑in overvoltage/overcurrent protection, ensuring stable operation in harsh industrial environments with IP65 protection against dust and moisture. ABB DSQC602’s modular design allows easy integration into robot control cabinets, reducing installation time and simplifying maintenance. ABB DSQC602 also supports hot‑swapping for I/O modules, enabling replacement without shutting down the robot system, which enhances production uptime.

Technical Parameters ABB DSQC602

| Parameter Item | Parameter Value |

|---|---|

| Product Model | ABB DSQC602 |

| Product Type | Digital I/O & Drive Interface Module (IRC5 Series) |

| Compatible Controller | ABB IRC5 Robot Controller |

| Core Function | Digital I/O signal processing, servo drive control, robot‑peripheral coordination |

| I/O Configuration | 16 digital inputs (24 VDC, sink/source), 16 digital outputs (24 VDC, 2 A per channel) |

| Signal Response Time | ≤1 ms (input/output) |

| Communication Interfaces | Profibus‑DP, DeviceNet, Ethernet |

| Supported Protocols | Profibus‑DP, DeviceNet, Ethernet/IP |

| Power Supply | 24 VDC (redundant inputs), max power consumption 15 W |

| Protection Features | Overvoltage, overcurrent, short‑circuit protection |

| Protection Level | IP65 (front panel), IP20 (module backplane) |

| Operating Temperature | -25°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Mounting | DIN‑rail or cabinet rack‑mounted |

| Dimensions | 150 mm × 100 mm × 60 mm (approx.) |

| Weight | 0.8 kg (approx.) |

| Certifications | CE, UL, RoHS |

| MTBF | > 400,000 hours |

| Warranty Period | 1 year |

Advantages and Features ABB DSQC602

- High‑Speed I/O Response: ≤1 ms signal latency of ABB DSQC602 enables precise synchronization between robot motion and external equipment, improving cycle time by 20% in high‑speed assembly lines.

- Robust Environmental Adaptability: IP65 protection and wide temperature tolerance of ABB DSQC602 ensure reliable operation in dusty, humid, or high‑temperature factory floors.

- Flexible Communication: Multi‑protocol support of ABB DSQC602 allows seamless integration with PLCs, HMIs, and other automation devices via Profibus‑DP/DeviceNet.

- Redundant Power & Protection: Dual power inputs and built‑in safeguards of ABB DSQC602 prevent downtime from power fluctuations or electrical faults.

- Hot‑Swappable Convenience: ABB DSQC602 supports hot‑swapping of I/O modules, cutting maintenance time by 70% and avoiding production interruptions.

- Easy Integration: Modular design of ABB DSQC602 fits standard IRC5 cabinets, reducing installation complexity and speeding up system commissioning.

Application Cases ABB DSQC602

- Automotive Welding Line: A car manufacturer used ABB DSQC602 in 20 IRB 6700 robots for body welding, leveraging fast I/O response to synchronize weld gun actuation with robot motion, reducing cycle time by 18% and improving weld quality consistency.

- Electronics Assembly: A consumer electronics plant deployed ABB DSQC602 for IRB 1200 robots, controlling 32 I/O points for component pick‑and‑place, using Profibus‑DP to connect to Siemens S7‑1500 PLCs and cutting changeover time by 22%.

- Material Handling Automation: A logistics center integrated ABB DSQC602 with IRB 4600 robots for palletizing, using DeviceNet to link conveyor systems, achieving 99.9% uptime via redundant power and hot‑swap capability.

- Food Packaging Line: A beverage plant utilized ABB DSQC602 for FlexPicker robots, with IP65 protection enabling operation in wet environments, reducing unplanned downtime by 30% compared to non‑protected modules.

Competitor Comparison

| Feature | ABB DSQC602 | ABB DSQC601 | Siemens SIMATIC ET 200SP |

|---|---|---|---|

| I/O Count | 16DI/16DO | 8DI/8DO | 16DI/16DO (max) |

| Signal Response | ≤1 ms | ≤2 ms | ≤1.5 ms |

| Communication Protocols | Profibus‑DP, DeviceNet, Ethernet/IP | Profibus‑DP only | PROFINET, Ethernet/IP |

| Protection Level | IP65 | IP54 | IP20 |

| Redundant Power | Yes | No | Optional |

| Hot‑Swappable | Yes | No | Yes |

| Price Range | Mid‑Range | Entry‑Mid Range | Mid‑High Range |

Selection Suggestions

- Choose ABB DSQC602 for ABB IRC5 robot systems to maximize I/O performance and seamless controller integration.

- Prioritize ABB DSQC602 for high‑speed robotics applications (welding, assembly, packaging) requiring ≤1 ms signal response and IP65 protection.

- Select ABB DSQC602 for systems needing redundant power, hot‑swap capability, or multi‑protocol communication with PLCs/HMIs.

Precautions

- Use a stable 24 VDC power supply (±10% tolerance) for ABB DSQC602 to avoid voltage‑related I/O signal errors.

- Ensure proper sealing of ABB DSQC602’s front panel to maintain IP65 protection in wet/dusty environments.

- Verify Profibus‑DP/DeviceNet communication parameters between ABB DSQC602 and IRC5 controllers before commissioning to ensure data synchronization.

- Follow safety guidelines when hot‑swapping modules on ABB DSQC602 to prevent electrical hazards and system malfunctions.

- Regularly inspect ABB DSQC602’s I/O channels for loose connections or corrosion, especially in high‑vibration industrial settings.

MVME147-022A

MVME162-023A

MVME162-026A PLC

MVME162-030 PLC

MVME162-031 PLC

MVME162-032 PLC

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922