Description

Product Overview and Introduction

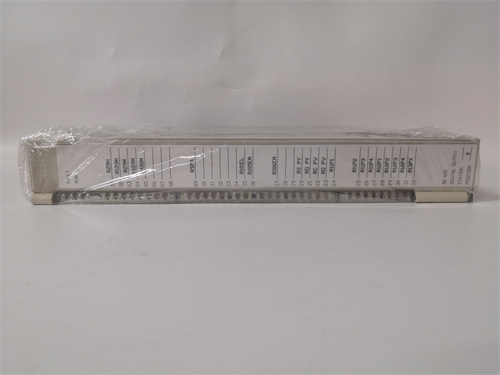

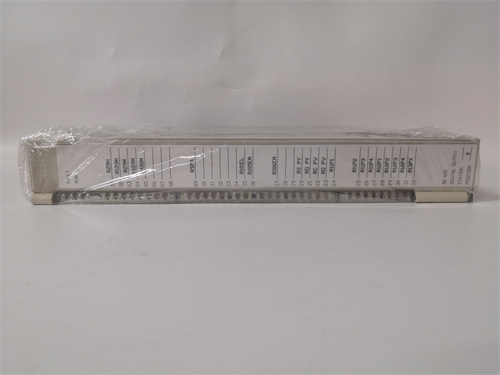

The ABB DO620 is a high-density digital output module from ABB’s S800 I/O family, a core component of the ABB Ability™ System 800xA and Compact Product Suite (AC 800M) distributed control systems (DCS). This module serves as a critical interface for executing control commands from the controller by switching field loads such as solenoid valves, motor starters, indicator lamps, and alarm annunciators. The ABB DO620 is engineered for reliability and performance in demanding industrial environments, providing a robust and efficient solution for outputting discrete control signals across a wide range of process and manufacturing applications.

Detailed Product Parameters and Specifications

The technical design of the DO620 is defined by its output characteristics and electrical ratings:

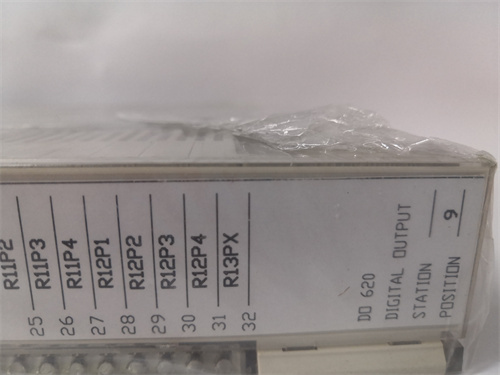

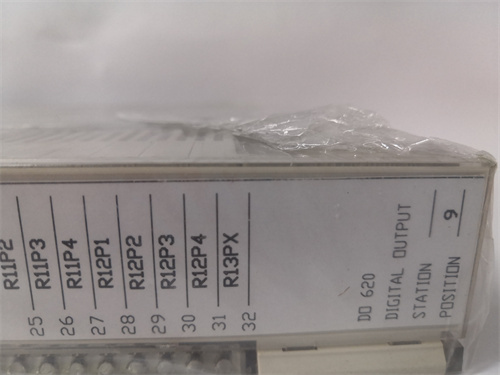

- Channel Configuration: 16 digital output channels, providing high-density output capability in a single module slot.

- Output Type: Sourcing (positive) transistor outputs. Each channel acts as a solid-state switch that sources current from the positive supply to the load.

- Output Voltage Rating: Typically designed for 24 V DC operation, compatible with standard industrial control voltage levels.

- Output Current Rating: Each channel can sink a specified maximum continuous current (e.g., 0.5 A per channel) with a higher possible inrush current for inductive loads like solenoids. The module also has a total group or module current limit.

- Switching Frequency: Capable of a high switching frequency, suitable for pulse-width modulation (PWM) applications such as controlling proportional valves or modulating heater power.

- Protection Features: Includes internal protection against short-circuits, overloads, and inductive kickback (typically with free-wheeling diodes or other suppression circuits).

- Status Indication: Each channel is equipped with an LED to indicate the output’s active (ON) state, providing clear visual diagnostics.

- Isolation: Channels are typically isolated in groups (e.g., 8 channels per common) from the internal logic and fieldbus, enhancing noise immunity and safety.

- Fieldbus Connection: Integrates with the controller via the S800 I/O’s internal fieldbus, connecting to the ABB MasterBus 300 network.

- Power Supply: Requires an external 24 V DC power supply for the output circuits, separate from the logic power drawn from the baseplate.

Key Advantages and Distinctive Features

The ABB DO620 module offers several distinct benefits for digital control applications:

- High Density and Compact Design: Sixteen outputs in a single module optimize control cabinet space and reduce system complexity, lowering installation and wiring costs.

- Robust and Reliable Performance: Designed with industrial-grade components and comprehensive electrical protection, ensuring long-term, maintenance-free operation even when switching inductive loads.

- Fast Switching Capability: The solid-state transistor outputs enable high-speed switching, making the module suitable for both standard on/off control and advanced applications like PWM control.

- Excellent Diagnostic Visibility: The per-channel LED indicators allow for instant visual verification of output status at the module, greatly simplifying troubleshooting and commissioning.

- Seamless System Integration: Fully configurable and diagnosable within the ABB Control Builder M or 800xA engineering environment, ensuring smooth integration into the control strategy and asset management system.

- Proven S800 I/O Platform: As a member of the widely deployed and trusted S800 I/O family, the ABB DO620 benefits from proven system compatibility, long-term availability, and global support.

Application Scenarios and Case Studies

This digital output module is ubiquitously used for final control element actuation:

- Chemical Batch Processing: Controlling solenoid valves for reagent dosing, agitator motor starters, and discharge valve actuators in a reactor system.

- Water Treatment: Automating pump motor starters, backwash valve sequences for filters, and chemical feed system actuators.

- Material Handling: Controlling conveyor motor contactors, diverter gate solenoids, and packaging machine actuators.

- HVAC Building Management: Starting and stopping fan motors, opening and closing damper actuators, and controlling compressor stages in large chiller plants.

- Manufacturing Assembly Lines: Actuating pneumatic cylinders, controlling robotic tool changers, and operating warning beacons and stack lights.

A typical application case is in a bottling plant’s filling line. Multiple ABB DO620 modules are used in S800 I/O stations to control the solenoid valves on each filler head, start the conveyor motors via motor starters, and activate warning lights. The fast and reliable switching ensures precise bottle filling and high-speed line operation, while the LED diagnostics allow maintenance staff to quickly identify a faulty valve solenoid.

Comparison with Competing Products

When compared to similar high-density digital output modules from competitors like Emerson (DeltaV CHARMs DO), Siemens (SIMATIC ET 200SP DQ), or Rockwell Automation (Point I/O), the ABB DO620 is a robust and competitive solution:

- Ecosystem Strength: Its primary advantage is guaranteed performance and streamlined engineering within the ABB 800xA/AC 800M ecosystem, which is a decisive factor for ABB DCS users.

- Output Type: The sourcing (PNP) transistor output is a common standard and compares directly with similar offerings from competitors. It is crucial to note the output type when replacing modules from other vendors that may use sinking (NPN) configurations.

- Density and Packaging: Its 16-channel density is standard and competitive. Some competitors may offer modules with fused outputs or different channel counts (e.g., 8, 32).

Competitors may offer advantages in areas such as universal channels (configurable as input or output), hot-swap capabilities in specific platforms, or different diagnostic granularity. The selection is typically driven by the overarching control system platform.

Selection Guidelines and Important Considerations

Selecting and applying the ABB DO620 requires careful electrical and system planning:

- Confirm System Compatibility: This module is designed for the ABB S800 I/O system. Verify compatibility with your specific S800 baseplate and AC 800M controller or CI communication interface.

- Load Characteristics are Critical: Determine the electrical characteristics of each load: voltage (must be 24V DC), current (must be within the channel’s and group’s continuous and inrush limits), and type (resistive, inductive, lamp). Inductive loads require proper suppression.

- Power Supply Sizing: The external 24V DC power supply for the output circuits must be sized to handle the sum of all simultaneous active channel currents, plus a safety margin. An undersized supply will cause voltage drops and erratic operation.

- Wiring and Protection: Use appropriately sized wire. For inductive loads, ensure suppression circuits (like external flyback diodes) are used if not internally provided. Fuse individual outputs or groups for critical loads.

- Configuration and Diagnostics: Configure each channel’s behavior (pulse, steady) in Control Builder M. Utilize the module’s diagnostic bits in the controller program to detect field-side faults like short circuits if supported.

- Installation and Safety: Ensure proper grounding of the external power supply and load commons. Follow lock-out/tag-out procedures during installation. For replacement, ensure the system is in a safe state and follow ESD precautions. Always refer to the official hardware manual for the ABB DO620, available via the product link, for specific wiring diagrams, torque settings for terminals, and safety instructions.

90232240 PLC

VMIVME-4140 PLC

PPC380AE01 PLC

HDS/HPN-14A-10-J6VA-AF1/REDUCER PLC

IS200TDBTH6ACD PLC DCS

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922