Description

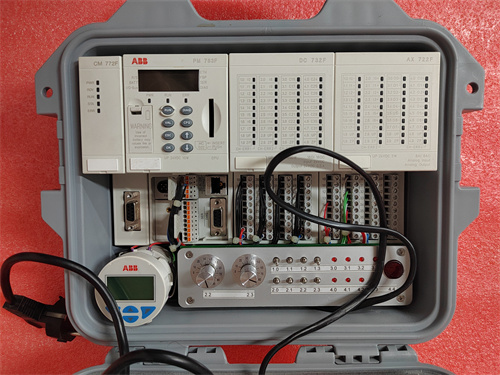

ABB DC732F 3BDH000375R0001 Process Controller

Product Description

The ABB DC732F 3BDH000375R0001 is a high-performance, single-loop digital process controller from ABB’s renowned CombiCare and Mod 300/Symphony family, designed for advanced regulatory control and sequencing in critical process applications. This controller serves as a dedicated, autonomous control unit capable of executing complex PID algorithms, feedforward control, and logic sequences for individual control loops, such as those managing temperature, pressure, flow, or level. Often deployed as a standalone device or integrated into larger DCS networks, the ABB DC732F provides exceptional reliability and precision for processes where control integrity is paramount. Engineered for demanding industrial environments, it offers robust construction and extensive configuration flexibility. For comprehensive technical documentation, programming manuals, and application guides, please visit the official product resource: ABB DC732F 3BDH000375R0001. The integration of the DC732F 3BDH000375R0001 into a process control strategy ensures a high level of availability and safety, often serving as a primary or backup controller for critical equipment like compressors, reactors, or boilers. Its stand-alone capability and sophisticated control features make the ABB DC732F a trusted solution for enhancing process stability and efficiency.

Product Parameters

- Product Model: ABB DC732F 3BDH000375R0001

- Series: ABB CombiCare / MOD 300 / Symphony Family.

- Device Type: Single-Loop Digital Process Controller.

- Control Functions: Advanced PID with auto-tuning, ratio/bias, feedforward, cascade control, and programmable logic (sequence control).

- Inputs:

- Analog Inputs: Typically accepts standard process signals (e.g., 4-20mA, thermocouple, RTD) for process variable (PV) and remote setpoint (SP).

- Digital Inputs: Multiple configurable inputs for interlock, run/stop commands, or status signals.

- Outputs:

- Analog Output: Primary 4-20mA output to the final control element (e.g., control valve, drive).

- Digital Outputs/Relays: Several configurable relay outputs for alarms, events, or logic control.

- Display & Interface: Features a built-in, configurable digital display for showing PV, SP, and output value, along with buttons for local manual control and parameter access.

- Communication: Equipped with serial communication ports (e.g., RS-485) supporting protocols like Modbus RTU for integration into DCS, SCADA, or PLC networks for monitoring and remote setpoint adjustment.

- Power Supply: Operates on standard industrial voltages (e.g., 100-240V AC, 24V DC).

- Housing: Compact, rugged metal housing designed for DIN-rail or panel mounting.

Advantages and Features

- High Control Accuracy and Stability: Provides precise regulatory control with advanced PID algorithms and adaptive tuning features, minimizing process variability and improving product quality.

- Autonomous Operation: Can function as a fully independent controller, ensuring process control continues even if a higher-level DCS or network fails, which is critical for safety and continuity.

- Flexible and Powerful Configuration: Combines continuous control with discrete logic capabilities in one device, allowing it to manage complex start-up sequences, interlocks, and batch steps without an external PLC.

- Robust and Reliable Design: Built for industrial environments with high immunity to electrical noise and wide operating temperature ranges, ensuring long-term reliability.

- Easy Local and Remote Access: The local display and keypad allow for manual operation and tuning at the device, while serial communication enables integration into plant-wide monitoring and control systems.

Application Cases in Various Fields

- Chemical Reactor Temperature Control: Serves as the primary temperature controller for an exothermic reactor, managing cooling valve position with PID and executing safe start-up/shutdown sequences with its built-in logic.

- Power Plant Deaerator Level Control: Maintains precise water level in a deaerator vessel by controlling the feedwater valve, using three-element (feedforward) control logic to respond to steam flow changes.

- Food & Beverage Pasteurization: Controls the temperature of a pasteurization plate heat exchanger, ensuring product is heated to a precise setpoint for a defined time to meet safety standards.

- HVAC Critical Air Handling Unit: Manages temperature and humidity in a cleanroom or laboratory by controlling heating coils, cooling valves, and humidifiers with integrated cascade loops.

Comparison with Competing Products

The ABB DC732F 3BDH000375R0001 competes with other advanced single-loop controllers from manufacturers like Yokogawa (UTAdvanced), Siemens (Sipart), and Honeywell (UDC). Its key advantages are its powerful combination of continuous and sequence control in one robust package, its heritage within the respected ABB MOD/Symphony systems, and its excellent communication capabilities. Compared to using a multi-loop DCS controller for a single critical loop, the DC732F offers dedicated hardware redundancy and often faster, more deterministic response. Versus simpler PID controllers, it provides vastly greater logic functionality and connectivity.

Selection Suggestions and Precautions

- Define Control Strategy Requirements: Clearly define if the application requires pure PID, complex cascade/ratio control, or significant sequential logic. The DC732F is ideal for mixes of these requirements. For simple loops, a basic controller may suffice.

- I/O Matching and Signal Compatibility: Verify that the controller’s input types (e.g., TC type, RTD wiring) match your sensor and that its analog output can drive your actuator (e.g., valve positioner current requirement). Ensure digital I/O counts are sufficient.

- Communication Needs: If integration with a host system is required, plan the communication network (e.g., Modbus RTU network layout) and ensure the correct cabling and configuration software are available.

- Configuration and Tuning Expertise: Effective use requires understanding of process control principles and access to the configuration software (e.g., ABB CombiCare tools). Proper tuning of PID and logic parameters is essential for optimal performance.

8406-113-WOODWARD PLC

HCMMO3MC-1A

STOBER-FAS4038 PLC

A06B-6044-H011

51451326-503 PLC

IPMON01 PLC

NTU-7Q2E

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922