Description

Product Description

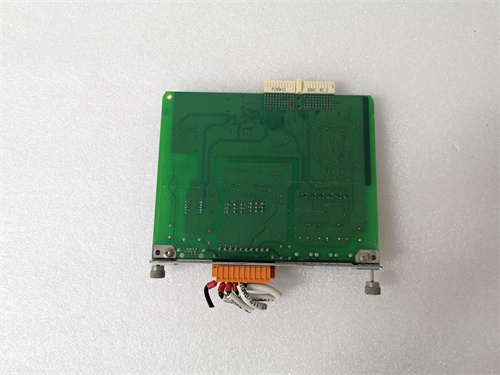

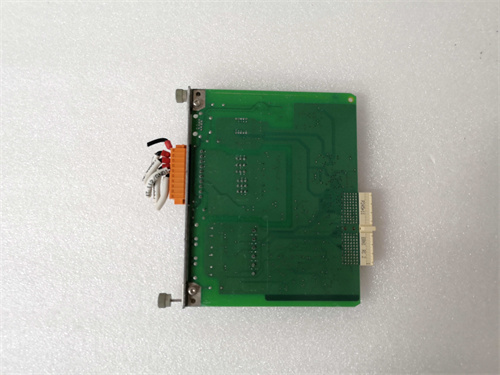

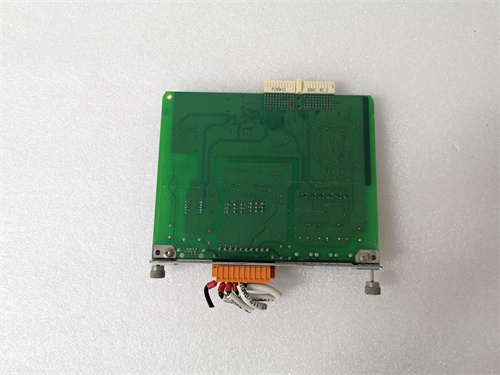

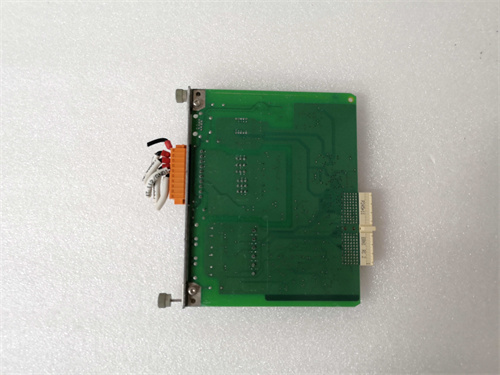

The ABB COM0003 is a versatile communication interface module, designated by the specific article code 2RAA005844A0006A, designed to provide robust network connectivity for ABB’s PLC and automation products, particularly within the AC 500 and AC500-eCo series. This module acts as a strategic gateway, enabling the programmable controller to communicate with higher-level systems such as SCADA, HMI, other PLCs, and enterprise networks. The primary function of the ABB COM0003 is to expand the communication capabilities of the base CPU by adding additional or alternative industrial network ports and protocols. By integrating this module, system architects can tailor the PLC’s connectivity to fit specific project requirements, whether for local device networking, remote monitoring, or integration into a larger distributed control architecture. Implementing the ABB COM0003 is a key step in building open, interoperable, and future-proof automation solutions that require reliable data exchange across different system layers.

Technical Parameters and Features

- Device Type: Communication interface module for PLC systems.

- Compatible Platform: Designed for the ABB AC 500 (PM5xx series CPUs) and AC500-eCo PLC families.

- Physical Interfaces: The specific variant 2RAA005844A0006A typically provides multiple physical ports. Common configurations include:

- Serial Ports: RS-232 and/or RS-485 ports for legacy or point-to-point connections.

- Ethernet Port: One or more RJ45 ports for 10/100 Mbit TCP/IP communication.

- Supported Protocols: The module’s firmware supports a range of industrial protocols, which may include:

- Fieldbus Masters/Slaves: Modbus RTU (on serial), Modbus TCP (on Ethernet).

- ABB Drives Communication: ABB’s native Drives Communication Protocol (e.g., for connecting to ACS drives).

- Other Protocols: PROFINET, EtherNet/IP, or CANopen support may be available in different COM0003 variants.

- Mounting: Plugs directly into a dedicated communication module slot on the left side of the compatible AC500 CPU unit.

- Configuration: Fully configured and programmed using ABB’s Automation Builder engineering suite, where the specific module type is selected, and protocol parameters are set.

Advantages and Key Features

- Enhanced Connectivity Flexibility: The ABB COM0003 module breaks connectivity limitations, allowing a single AC500 CPU to communicate on multiple networks simultaneously (e.g., Modbus TCP for SCADA and a serial link to a legacy device).

- Seamless Ecosystem Integration: As a genuine ABB component, it integrates perfectly with the AC500 hardware and Automation Builder software, ensuring reliable operation, simplified configuration, and access to technical support.

- Open Protocol Support: By supporting widely adopted standards like Modbus and Ethernet/IP, the COM0003 facilitates easy integration with equipment from various third-party manufacturers, promoting an open automation philosophy.

- Compact and Integrated Design: It extends the controller’s functionality without requiring additional external gateways or bulky hardware, saving panel space and reducing points of failure.

- Future-Proofing: The modular approach allows users to select or upgrade communication capabilities as network standards evolve or project needs change, protecting the investment in the core CPU.

Application Case Studies in Various Fields

- Water/Wastewater Treatment: An AC500 PLC with a COM0003 module uses its Modbus TCP port to communicate with the plant-wide SCADA system while using its RS-485 port to poll a chain of remote I/O units or flow meters via Modbus RTU across the treatment site.

- Factory Automation (Machine Building): On a packaging machine, the PLC uses the ABB COM0003 to act as a PROFINET controller (if so equipped) for high-speed communication with distributed servo drives and I/O stations, while a second port handles HMI connectivity.

- Renewable Energy: In a biogas plant, the module enables the control system to gather data from gas analyzers and meters over serial Modbus while simultaneously sending performance data to a central management server via Ethernet.

- Material Handling: For a conveyor system, the COM0003 facilitates communication between multiple PLCs over an Ethernet network for coordinated control and provides a serial interface for configuring motor drives.

Comparison with Competing Products

Compared to using the CPU’s built-in ports alone or employing external protocol converters, the ABB COM0003 offers a more elegant and reliable solution:

- Native Performance vs. External Add-on: The COM0003 is an integrated part of the PLC’s hardware and firmware, offering better performance, deterministic handling of protocol stacks, and unified diagnostics compared to an external black-box converter.

- Unified Engineering Environment: Its configuration is managed entirely within Automation Builder. This contrasts with external converters that require separate, often proprietary, configuration tools, complicating project management and troubleshooting.

- Optimized for the Platform: It is designed to leverage the AC500’s processing power and memory management specifically for communication tasks, ensuring stability and reliability that generic third-party modules may not guarantee.

Selection Advice and Important Notes

- Verify Exact Protocol Suite: The article number 2RAA005844A0006A defines a specific protocol and port combination. It is crucial to obtain the precise data sheet for this variant to confirm the supported protocols (e.g., Modbus TCP/RTU, PROFINET) before purchase to ensure it meets your network design.

- Check CPU and Firmware Compatibility: Ensure your AC500 or AC500-eCo CPU model and its firmware version are compatible with the COM0003 module and support the desired protocols. Compatibility lists are available in Automation Builder or ABB manuals.

- Plan Network Architecture Early: Define all communication needs (protocols, number of connections, data rates) during the design phase to select the correct ABB COM0003 variant and avoid costly changes later.

- Secure Configuration Backup: Always archive the complete Automation Builder project, including the communication configuration for the COM0003 module. This is essential for disaster recovery and future modifications.

- Consider Cybersecurity: When enabling Ethernet connectivity, implement appropriate network security measures at the switch and firewall level. Use features like IP address filtering and disable unused services on the module if supported.

DA3284-C PLC/PC

CP6500-V PLC

Q8344A PLC

IC697CPX928 PLC

MTS-P01.2 MTS-P01.2-D2-B1-NN-NN R911286030 PLC06S-M05-06V18 PLC

1794-APB PLC

1398-DDM-009

1C31169G02 PLC/PC

mvme162-213 Motorola MVME 162-223 PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922