Description

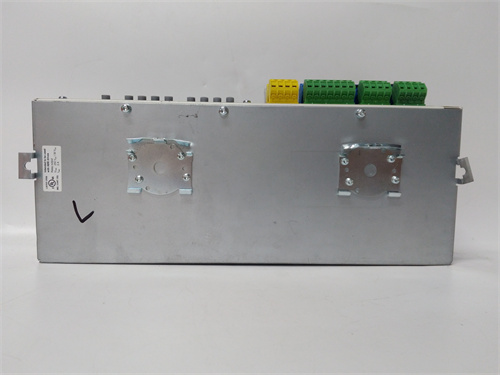

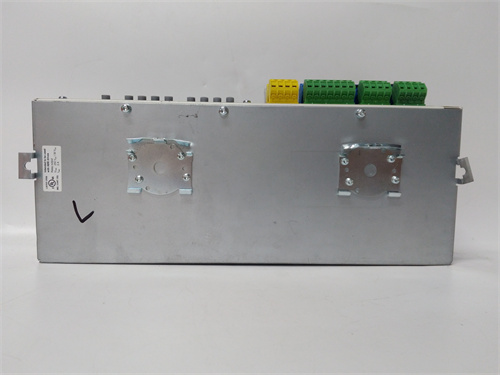

Product Description

The ABB BCU-12 is a high-performance communication and control module designed for ABB’s Symphony Harmony and Advant distributed control systems. This module serves as a Basic Controller Unit, functioning as an intelligent, programmable automation controller for managing dedicated process units or subsystems. The BCU-12 integrates a powerful processor, memory, and communication interfaces to execute complex control strategies, handle sequential logic, and manage data exchange within the larger DCS network. Integrating the ABB BCU-12 controller into a Harmony system provides a distributed and scalable architecture, allowing for robust and reliable control of specific plant areas.

Product Parameters and Specifications

- Product Type: Basic Controller Unit (Programmable Automation Controller) for Symphony Harmony.

- Compatible Systems: ABB Symphony Harmony, Advant DCS.

- Processor: Features a dedicated high-performance microprocessor for executing control algorithms.

- Memory: Contains both volatile (RAM) and non-volatile (Flash) memory for the operating system, application program, and data storage.

- Communication Interfaces:

- Control Network: Connects to the Harmony INFI-NET (or later network) for peer-to-peer communication with other controllers and operator stations.

- I/O Network: Interfaces with S800 I/O stations via a high-speed serial link (e.g., MasterBus).

- Service Port: Typically an RS-232/485 port for engineering access and configuration.

- Control Capabilities: Executes continuous control, batch/sequential control, and advanced calculations using ABB’s control function blocks.

- Redundancy: Supports controller redundancy (1:1) for high-availability applications, where a standby BCU-12 can take over seamlessly if the primary fails.

- Programming: Configured and programmed using ABB’s Composer or Control Builder engineering tools.

Advantages and Features

- Distributed Processing Power: The ABB BCU-12 decentralizes control logic, moving processing closer to the field I/O. This reduces load on central supervisory systems, improves system responsiveness, and enhances overall reliability by containing faults within a specific controller domain.

- Seamless Symphony Harmony Integration: As a native Harmony component, it offers flawless integration within the DCS architecture. It participates in global data sharing, uses unified engineering tools, and appears as a standard node in the operator interface, ensuring consistency across the plant.

- Robust and Deterministic Performance: Engineered for real-time industrial control, the BCU-12 provides deterministic execution of control loops and sequences, which is critical for maintaining stable and safe process operations.

- Scalable and Flexible Architecture: The modular design allows multiple BCU-12 units to be deployed across a plant, each controlling a specific area (e.g., a boiler, a distillation column). This scalability makes the system adaptable to plants of any size.

- High Availability through Redundancy: The option for controller-level redundancy ensures continuous operation of critical processes. The switchover between primary and standby controllers is bumpless and transparent to the process.

Application Cases in Various Fields

- Power Generation (Boiler Control): Serves as the dedicated controller for a boiler island, managing fuel, air, and feedwater control loops independently within the larger plant DCS.

- Chemical Processing (Reactor Control): Acts as the primary controller for a batch or continuous reactor, handling complex temperature, pressure, and sequencing logic.

- Oil & Gas (Compressor Control): Manages anti-surge and performance control for critical centrifugal compressors in pipeline stations or refineries.

- Water Treatment (Process Train): Controls a complete treatment train (e.g., clarification, filtration, disinfection) as an autonomous unit within a larger SCADA system.

Comparison with Competing Products

- vs. Centralized DCS Controller: In a purely centralized system, one large controller handles everything. The distributed BCU-12 approach offers better fault containment, easier scalability, and reduced network loading.

- vs. Standalone PLCs: A standalone PLC would require separate engineering tools and complex gateways to integrate with the DCS. The ABB BCU-12 is a fully integrated component of the Symphony ecosystem, offering superior data integration, security, and a unified operational view.

- vs. Other DCS Vendor Distributed Controllers (e.g., Emerson Ovation Controller): Competing systems offer similar distributed architectures. The BCU-12 is distinguished by its specific integration with ABB’s S800 I/O, use of the Harmony network, and configuration within ABB’s Composer/Control Builder environment.

Selection Suggestions and Precautions

- System Architecture Planning: The BCU-12 must be part of a planned Harmony system with appropriate network switches (INFI-NET), I/O drops (S800), and engineering stations. It is not a standalone controller.

- Redundancy Configuration: For critical applications, plan for a redundant controller pair from the start. This requires specific hardware (two BCU-12s, redundancy module) and careful software configuration.

- Software and Firmware Compatibility: Ensure the BCU-12 firmware version is compatible with the version of the Composer engineering software and the overall Harmony system software release.

- Memory and Processing Load: When developing the control application, monitor the processor and memory load of the BCU-12. Overloading the controller can lead to increased scan times and degraded performance.

- Expert Engineering Required: Configuration and programming of the BCU-12 require specialized training on ABB’s Symphony Harmony system and its engineering tools. It is not programmed with standard IEC 61131-3 languages in a generic environment.

9907-774 PLC

9907-806

9907-954 I/O

9907-955 PLC

9907-957 PC

9907-994 PLC

9907-019 PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922