Description

Product Overview and Introduction

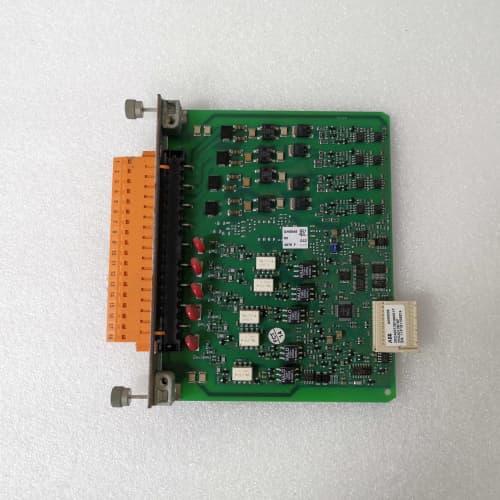

The ABB AIM0016 is a versatile and high-performance analog input module from ABB’s extensive automation portfolio, specifically designed for the AC 800M controller family within the ABB Ability™ System 800xA. This module serves as a critical interface for connecting a wide array of analog sensors—such as pressure, temperature, flow, and level transmitters—to the central control system. The ABB AIM0016 is engineered to provide precise, reliable, and isolated measurement of standard industrial signals, converting them into digital data for monitoring, control, and advanced process optimization.

Detailed Product Parameters and Specifications

The technical capability of the AIM0016 is defined by its configurable channels and electrical characteristics:

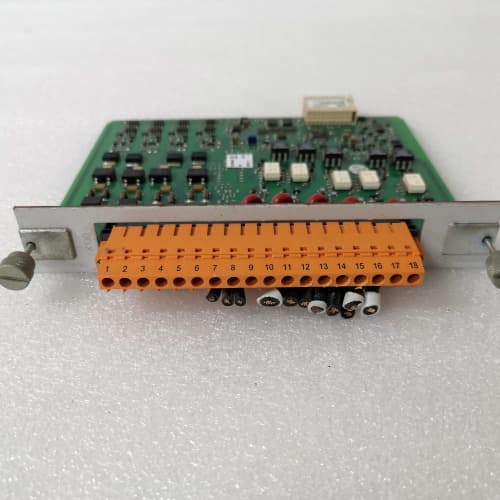

- Channel Configuration: 16 analog input channels, offering high-density signal acquisition in a single module footprint. Channels are typically single-ended.

- Input Signal Types: Each channel is software-configurable to accept a range of standard process signals:

- Current: 4-20 mA (with internal precision sampling resistor).

- Voltage: 0-10 V DC, ±10 V DC.

- Resistance: For direct connection of 2- or 3-wire Resistance Temperature Detectors (RTDs), such as Pt100 and Pt1000.

- Thermocouple: Direct connection of common thermocouple types (e.g., J, K, T, E, N, B, R, S).

- Resolution: High-resolution analog-to-digital conversion, typically 16-bit, ensuring accurate representation of the process variable.

- Accuracy: High typical accuracy (e.g., ±0.05% of range) under reference conditions, which is critical for precise control loops and reliable process data.

- Sampling Rate: Features individually configurable conversion times per channel, balancing speed and noise filtering for optimal performance in process applications.

- Isolation: Channels are isolated in groups (e.g., 8 channels per common) from the internal electronics and the fieldbus, providing protection against ground loops and electrical noise.

- Diagnostics: Comprehensive per-channel diagnostics for conditions such as open wire (sensor break), under-range, and over-range.

- Fieldbus Connection: Integrates with the AC 800M controller via the S800 I/O high-speed internal fieldbus (MasterBus 300).

- Power Supply: Powered from the S800 I/O station’s backplane.

Key Advantages and Distinctive Features

The ABB AIM0016 module offers significant advantages for complex process measurement:

- Exceptional Versatility and Density: The ability to mix 16 channels of different signal types (mA, V, RTD, TC) on a single module provides unmatched application flexibility, dramatically reducing spare part variety and cabinet space requirements.

- High Accuracy and Stability: Engineered with premium components and advanced signal conditioning, it delivers stable, drift-free measurements essential for advanced process control, quality assurance, and regulatory compliance.

- Direct Sensor Connection: Eliminates the need for external signal transmitters or conditioners for RTDs and thermocouples, lowering system cost, complexity, and potential failure points.

- Advanced Diagnostics and Maintenance: Detailed channel-level diagnostics enable predictive maintenance by identifying failing sensors (open circuit) or process abnormalities early, reducing unplanned downtime.

- Seamless 800xA Integration: Fully configured, scaled, and diagnosed within the ABB Control Builder M engineering environment, providing a unified workflow from design to operation within the System 800xA.

- Robust Industrial Design: Built to withstand harsh industrial environments with high immunity to electromagnetic interference (EMI) and vibration. The ABB AIM0016 is a cornerstone for building reliable and scalable process automation systems.

Application Scenarios and Case Studies

This universal analog input module is deployed across a vast spectrum of continuous and batch processes:

- Oil & Gas Production: Measuring wellhead pressures, separator temperatures (RTD), pipeline flows (4-20mA), and analyzer outputs on offshore platforms.

- Pharmaceutical & Biotechnology: Monitoring critical process parameters (CPPs) like bioreactor temperature (RTD), pressure, pH (4-20mA), and dissolved oxygen in sterile manufacturing.

- Chemical Processing: Acquiring data from reactor temperatures (thermocouples), distillation column pressures, and catalyst feed rates across a large petrochemical plant.

- Power Generation: Measuring temperatures at multiple stages of a heat recovery steam generator (HRSG), feedwater flow, and auxiliary system pressures in a combined cycle plant.

- Food & Beverage: Monitoring pasteurization temperatures, tank levels, and blending recipe flows in a dairy or beverage processing facility.

A typical application case is in a large chemical reactor. A single ABB AIM0016 module is configured with channels for multiple RTDs (for jacket and internal temperature), 4-20mA inputs for reactor pressure and agitator power, and a thermocouple for a high-temperature safety point. This consolidation simplifies I/O hardware, while the module’s high accuracy ensures precise reaction control and product quality.

Comparison with Competing Products

Compared to similar high-density, universal analog input modules from competitors like Emerson (DeltaV CHARM AI card), Siemens (SIMATIC ET 200SP AI 8xU/I/RTD/TC), or Yokogawa (FA-M3 AI modules), the ABB AIM0016 is a leading contender:

- Channel Density and Flexibility: Offering 16 truly universal channels in one module is a competitive advantage over many 8-channel alternatives, providing superior point density.

- Deep Integration with 800xA: Its most significant advantage is the native, object-level integration within the ABB System 800xA, offering superior engineering efficiency and operational diagnostics compared to third-party I/O integrated via gateways.

- Proven Performance in Critical Processes: The S800 I/O platform, including the AIM0016, has a long, proven track record in the most demanding continuous processes, which builds user confidence.

Competitors may offer advantages in areas such as hot-swap capabilities in specific platforms, different physical form factors, or slightly faster update rates for all channels. The choice is fundamentally influenced by the selected DCS/PLC platform and the total cost of ownership over the system lifecycle.

Selection Guidelines and Important Considerations

Proper selection and application require meticulous planning:

- System Architecture Confirmation: The ABB AIM0016 requires an AC 800M controller and a compatible S800 I/O station (e.g., S800L). Verify the module is supported in your specific system configuration and firmware revision.

- Detailed Channel Planning: Before installation, define the signal type, range, and scaling for each channel in the engineering software. This dictates the wiring configuration (2-wire, 3-wire, 4-wire for RTDs).

- Wiring and Grounding Best Practices: Use high-quality, shielded twisted-pair cable for all analog signals. Adhere to strict single-point grounding rules to avoid ground loops, crucial given the channel group isolation.

- Sensor and Power Supply Considerations: Ensure field transmitters are loop-powered or have their own supply as required. For RTDs, use the correct wiring configuration to compensate for lead resistance.

- Software Configuration and Diagnostics: Utilize Control Builder M to configure filtering, alarming, and to enable hardware diagnostics. Program the controller to react to diagnostic bits (e.g., sensor fault) for automated alerts.

- Installation and Calibration: Ensure the module is securely seated in the baseplate. While highly accurate, critical loops may require on-site calibration verification. For all electrical, mechanical, and configuration details, always consult the official hardware manual for the ABB AIM0016, accessible via the product link. Be mindful that when using all 16 channels with slow filtering, the overall module update time is the sum of individual channel conversion times.

1C31125G03 PLC EMERSON

1C31129G01 PLC

1C31129G02 PLC EMERSON

1C31129G04 EMERSON

1C31142G01 plc

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922