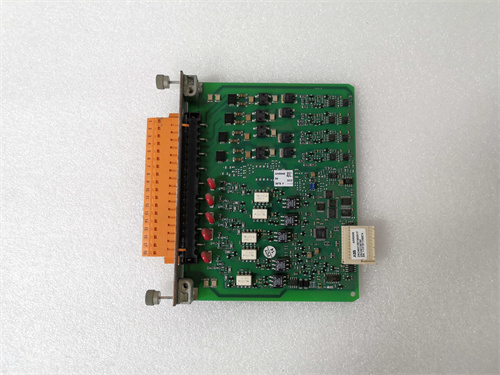

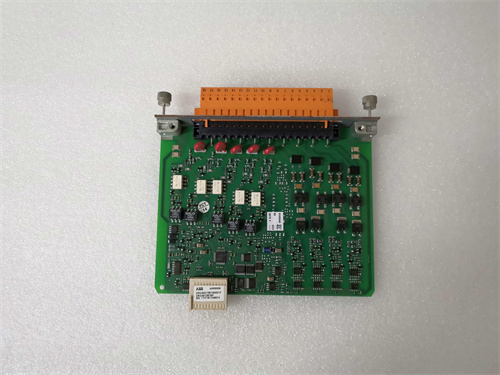

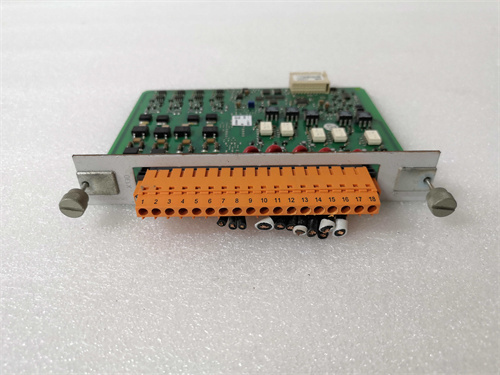

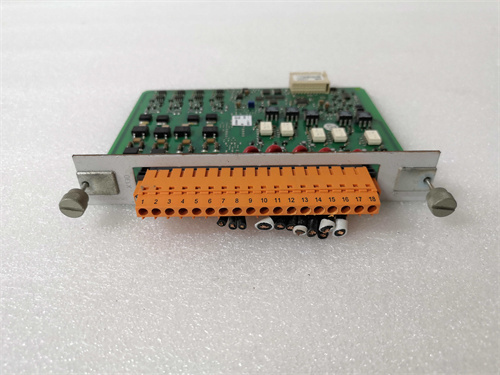

Description

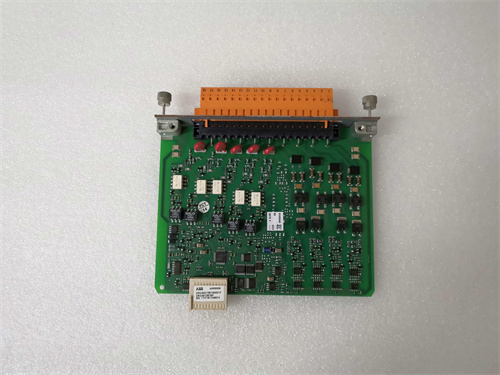

ABB AIM0016

1. Product Description

2. Key Technical Parameters

| Parameter Category | Specific Specifications |

|---|---|

| Device Type | Analog input module for ABB AC500 PLC series |

| Number of Input Channels | 16 (independent channels, no cross-interference) |

| Input Signal Type | 4…20 mA (standard industrial signal; compatible with active/passive sensors) |

| Conversion Accuracy | ±0.1% of full scale (0…50°C) |

| Resolution | 16-bit |

| Isolation Protection | 2500V galvanic isolation per channel (between channels, and between channels and ground) |

| Protection Functions | Short-circuit protection per channel; signal overload protection |

| Hot-Swap Support | Yes (requires enabling hot-swap in ABB AC500 PLC system) |

| Signal Filtering | Digital filtering; adjustable frequency (0.1…10 Hz via software) |

| Mounting Method | Compatible with ABB AC500 PLC racks (works with AC500-CPU, AC500-eCo series CPUs) |

| Dimensions | 120 mm (L) × 80 mm (W) × 20 mm (H) |

| Protection Rating | IP20 |

| Operating Temperature | -25…60°C |

| Operating Humidity | 5…95% (non-condensing) |

| Power Supply | Powered via PLC rack (24V DC; maximum power consumption ≤120 mA) |

| Compatible Software | ABB Automation Builder (for module configuration and diagnostics) |

3. Advantages and Features

- Cost-Effective Multi-Channel Design: 16 independent channels allow simultaneous signal collection from 16 sensors, reducing PLC rack space and equipment costs compared to 8-channel or 4-channel modules. This is ideal for scenarios requiring extensive analog monitoring (e.g., multi-point water quality monitoring systems, multi-reactor chemical plants).

- Precise and EMI-Resistant Signal Processing: ±0.1% accuracy and 2500V isolation ensure stable, accurate signal output even in complex industrial environments, preventing control errors caused by signal interference and safeguarding process stability and product quality.

- High-Availability Hot-Swap: Minimizes maintenance downtime and avoids economic losses from unplanned shutdowns, making it perfect for continuous-production enterprises.

- Easy Maintenance and Diagnostics: LED indicators combined with software diagnostics enable quick fault localization (e.g., short-circuited channels, faulty sensors), reducing maintenance complexity and costs.

- Broad Environmental Adaptability: Wide temperature and humidity ranges, plus IP20 protection, allow use in diverse industrial settings, eliminating 选型 challenges due to environmental constraints.

4. Typical Application Cases

- Petrochemical Industry – Pipeline Pressure Monitoring: In oil transmission pipelines, pressure sensors are installed at intervals to monitor internal pressure (preventing pipe bursts from overpressure or inefficient transmission from underpressure). ABB AIM0016 collects 4…20 mA signals from 16 pressure sensors and transmits data to the PLC. If pressure is abnormal, the PLC triggers alarms or adjusts valves to ensure safe pipeline operation.

- Chemical Pharmaceutical Industry – Reactor Temperature Control: During pharmaceutical synthesis, real-time temperature monitoring at multiple reactor locations is critical to maintaining reaction stability. ABB AIM0016 collects signals from temperature sensors (e.g., PT100 RTDs converted to 4…20 mA via transmitters) and sends data to the PLC. The PLC adjusts heating/cooling systems based on temperature data to avoid purity issues from temperature fluctuations.

- Energy and Power Industry – Generator Cooling Water Temperature Monitoring: Overheating of cooling water in thermal power plant generators reduces lifespan and efficiency. ABB AIM0016 collects temperature signals from cooling water sensors (converted to 4…20 mA) and feeds data to the PLC. If temperatures exceed thresholds, the PLC activates backup cooling equipment to ensure stable generator operation.

- Food Processing Industry – Level Control: In food storage tanks (e.g., milk, juice), level sensors (e.g., ultrasonic level meters outputting 4…20 mA) prevent overflow or empty tanks. ABB AIM0016 collects these signals and transmits them to the PLC, which controls inlet/outlet valves for automated level management.

5. Comparison with Competitors

| Comparison Dimension | ABB AIM0016 | Siemens SIMATIC S7-1200 SM 1231 (8-channel) | Schneider Modicon M340 BMXAi1602 (16-channel) |

|---|---|---|---|

| Number of Input Channels | 16 | 8 | 16 |

| Conversion Accuracy | ±0.1% of full scale | ±0.5% of full scale | ±0.2% of full scale |

| Isolation Protection | 2500V per channel | Group isolation (4 channels per group) | 2500V per channel |

| Hot-Swap Support | Yes | No | Yes |

| Compatible PLC Series | ABB AC500 series | Siemens S7-1200 series | Schneider Modicon M340 series |

| Key Advantages | High accuracy, strong EMI resistance, cost-effective for AC500 systems | Ideal for small-point monitoring with S7-1200 | High accuracy, but higher cost than ABB AIM0016 |

6. Selection Recommendations

- Based on Channel Count: If you need to monitor ≤16 analog points, ABB AIM0016 is optimal. For >16 points, multiple modules can be stacked to leverage its multi-channel cost advantage.

- Based on Accuracy Requirements: For high-precision scenarios (e.g., pharmaceutical production, precision chemical processing), ABB AIM0016’s ±0.1% accuracy meets demands. For lower-precision needs (e.g., general environmental monitoring), more economical modules may suffice—but ensure they include industrial-grade EMI protection.

- Based on PLC Model: ABB AIM0016 is exclusively compatible with the ABB AC500 series. For other PLC brands (e.g., Siemens, Schneider), select brand-matched modules. For new projects leaning toward ABB PLC systems, ABB AIM0016 is the ideal analog acquisition partner.

- Based on Maintenance Needs: If on-site maintenance requires frequent module replacement or no downtime, ABB AIM0016’s hot-swap function is a critical selection factor.

7. Usage Precautions

- Installation and Wiring: Disconnect PLC power before installation (except for hot-swap). Strictly follow polarity guidelines when wiring sensors to avoid damaging the module or sensors. Use shielded cables for sensor connections, with the shield grounded at one end to enhance EMI resistance.

- Avoid Over-Ranging: Ensure sensor output signals stay within 4…20 mA. For scenarios where signals may exceed 20 mA (e.g., abnormal operating conditions), install current-limiting resistors between the sensor and module to prevent channel damage.

- Software Configuration Tips: When configuring via ABB Automation Builder, correctly set the signal type (4…20 mA) and filtering frequency (adjust based on on-site EMI—higher frequencies for heavy interference). Enable channel diagnostics to detect faults early.

- Regular Maintenance: Periodically check LED statuses for abnormal alarms. Calibrate module accuracy via software every 6–12 months to ensure long-term precision. For modules in high-temperature or dusty environments, clean the surface regularly to prevent overheating.

- Spare Parts Management: For critical production systems, stock 1–2 spare ABB AIM0016 modules to minimize downtime in case of failures

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922