Description

Product Overview and Introduction

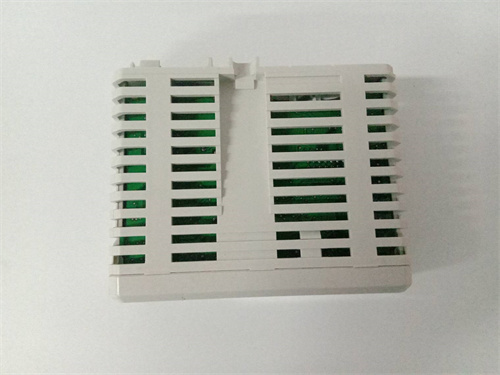

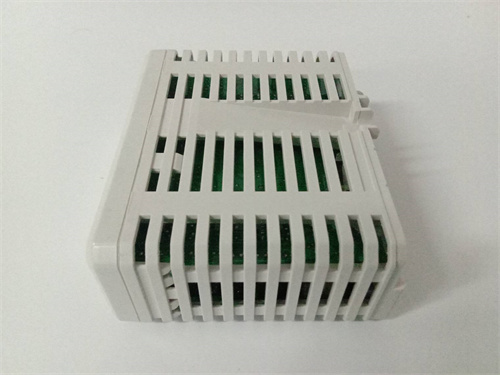

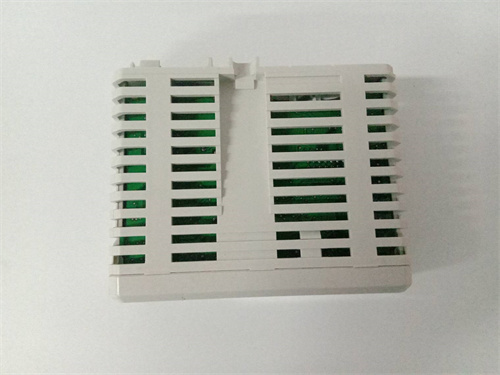

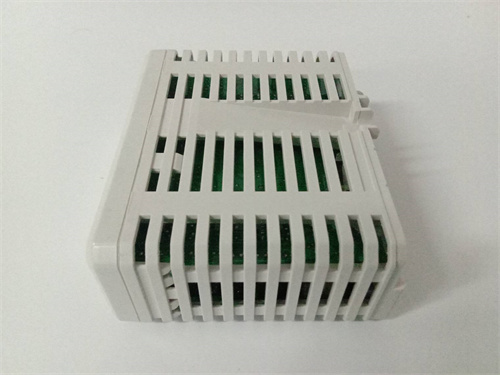

The ABB AI801 is a flexible, 8-channel analog input module from the ABB Freelance distributed control system (DCS) and AC 700F controller series. This module serves as a versatile interface for connecting a wide variety of analog sensors and transmitters to the control system, converting real-world process signals—such as those for temperature, pressure, level, and flow—into precise digital values for monitoring and control. Designed for mid-range automation applications, the ABB AI801 combines ease of use with the robustness required for industrial environments.

Detailed Product Parameters and Specifications

The module’s capability is defined by its configurable input channels and electrical specifications:

- Channel Configuration: 8 analog input channels, configurable per channel via software/hardware for different signal types.

- Input Signal Types: Each channel can be individually configured to accept:

- Voltage: 0-10 V, ±10 V.

- Current: 0-20 mA, 4-20 mA (with internal 125-ohm resistor).

- Resistance: For direct connection of RTD sensors (e.g., Pt100, Pt1000).

- Thermocouple: Direct connection of common thermocouple types (e.g., J, K, L, N, T, U).

- Resolution: High-resolution analog-to-digital conversion (typically 16-bit), ensuring accurate measurement.

- Accuracy: High typical accuracy (e.g., ±0.1% of range) for reliable process data.

- Sampling Rate: Specified update rate per channel, suitable for process control applications.

- Input Impedance: High input impedance for voltage inputs to minimize signal loading.

- Isolation: Channels are typically isolated in groups (e.g., 4 channels per common) from the internal logic and fieldbus.

- Diagnostics: Comprehensive channel diagnostics for open circuit, under-range, and over-range conditions.

- Fieldbus Connection: Integrates with the controller via the Freelance/AC 700F local I/O bus (CI801 communication interface).

- Power Supply: Powered from the system’s backplane via the associated communication interface module.

Key Advantages and Distinctive Features

The ABB AI801 offers significant benefits for versatile process measurement:

- Exceptional Channel Flexibility: The ability to mix different sensor types (voltage, current, RTD, TC) on a single module provides outstanding application flexibility, reducing spare part variety and simplifying system design.

- Direct Sensor Connection: Eliminates the need for external signal transmitters or conditioners for RTDs and thermocouples, lowering overall system cost and complexity.

- Compact and Efficient Design: Eight channels in a compact module save valuable cabinet space and reduce the number of modules required for a given application.

- Seamless System Integration: Fully configured and diagnosed within the ABB Freelance Engineering Studio or Control Builder F software, ensuring smooth integration into the control strategy and asset management.

- Robust Industrial Construction: Built to withstand typical industrial environmental conditions with protection against electromagnetic interference.

- Cost-Effective Solution: Provides a high degree of functionality at a competitive price point, making it an economical choice for a wide range of applications within the Freelance ecosystem. The versatility of the ABB AI801 makes it a fundamental building block for many process automation projects.

Application Scenarios and Case Studies

This module is widely used in industries employing the Freelance DCS for process and machine control:

- Water and Wastewater Treatment: Measuring pH (4-20mA), chlorine level, tank levels (4-20mA), and temperature (Pt100) of process streams.

- Food and Beverage: Monitoring temperatures (thermocouples) in pasteurizers, pressures (4-20mA) in filtration systems, and recipe ingredient flows.

- HVAC and Building Automation: Controlling large commercial systems by measuring duct pressures, water temperatures (RTD), and valve positions (0-10V).

- Manufacturing and Machinery: Acquiring data from load cells (0-10V), position sensors, and multiple temperature points on an industrial oven or mixer.

A typical application case is a small brewery automation system. A single ABB AI801 module is used to measure the temperature of multiple fermentation tanks (using Pt100 RTDs), monitor the pressure in the CO2 lines (4-20mA), and measure the level in the bright beer tank (4-20mA). This consolidation of different signal types onto one module simplifies the I/O layout and reduces costs.

Comparison with Competing Products

Compared to similar universal analog input modules from competitors like Siemens (ET 200SP AI 8xU/I/RTD/TC), Schneider Electric (Modicon M580 analog modules), or Rockwell Automation (CompactLogix 1769-IF8), the ABB AI801 holds a strong position within its specific ecosystem:

- Freelance Ecosystem Optimization: Its primary advantage is seamless integration, configuration, and diagnostics within the ABB Freelance and AC 700F controller environment, offering a cohesive user experience.

- Flexibility vs. Simplicity: It offers a high degree of per-channel flexibility, similar to top competitors. Some competing modules may offer higher channel counts or different diagnostic features, but the AI801 provides a well-balanced feature set for its target market.

- Total Cost of Ownership: For projects based on the Freelance system, it provides an optimal balance of performance and cost. Migrating to a competitor would require a change of the entire control platform.

Competitors may offer advantages in terms of faster sampling rates, higher channel density, or native integration with different fieldbus protocols (e.g., PROFINET, EtherNet/IP). The choice is fundamentally driven by the selected controller platform.

Selection Guidelines and Important Considerations

Proper selection and configuration are key to leveraging the module’s flexibility:

- Confirm System Compatibility: The ABB AI801 requires an ABB Freelance controller (e.g., AC 700F) and a compatible communication interface module (e.g., CI801) in the local I/O rack.

- Plan Channel Configuration: Before wiring, plan the signal type for each channel. Configuration is done in the engineering software, but physical wiring (2-wire, 3-wire, 4-wire for RTDs) must match the selected type.

- Sensor and Wiring Best Practices: Use shielded, twisted-pair cables for analog signals. For thermocouples, use the correct matching extension wire. Ensure proper grounding to avoid ground loops, especially given the channel group isolation.

- Software Configuration: Utilize the engineering studio to configure each channel’s type, scaling, filter time, and alarm limits. The software will also indicate the correct terminal connections for the selected signal type.

- Diagnostic Utilization: Program the controller to monitor the module’s diagnostic bits (available via the software) to detect field-side faults like sensor break (open circuit) for proactive maintenance.

- Installation and Calibration: Ensure the module is securely seated in the rack. While the module is highly accurate, critical measurement loops may require onsite calibration against a standard. Always consult the hardware manual for the ABB AI801, available via the product link, for specific wiring diagrams, terminal assignments, and technical limits. Remember that when mixing signal types, the overall module update time is the sum of the conversion times for all active channels.

PYRPB10E100 I/O

P50B08075HXS1J PLC

RS1A15AA PLC DCS

AP-3M120B1C1 PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922