Description

Product Description

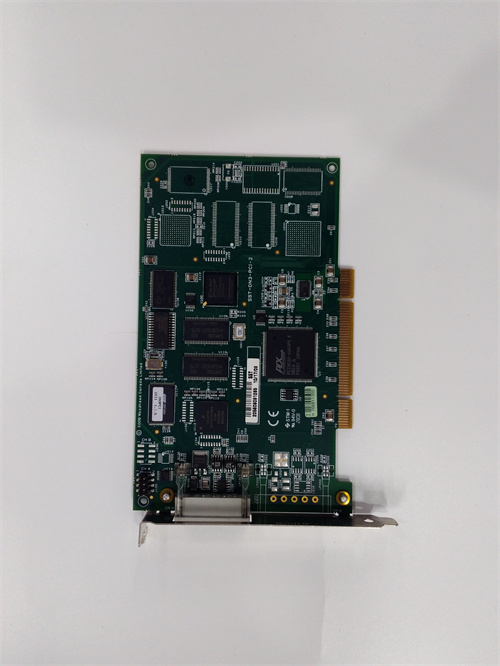

The ABB 3HAC6157-1 is a critical and specialized spare part from ABB’s robotics division, specifically designed for their industrial robot arms. This part is a Drive Module or Axis Computer Board, which serves as the intelligent motor controller for one or more axes (joints) of an ABB robot, such as those in the IRB 6600 or IRB 6700 series. The primary function of the ABB 3HAC6157-1 is to execute high-speed, closed-loop control of a brushless servo motor. It receives motion commands from the robot’s main controller (IRC5 or OmniCore), processes feedback from the motor’s resolver or encoder, and generates the precise PWM (Pulse Width Modulation) signals to drive the associated power amplifier (inverters located in the Drive Module unit). For maintenance engineers and system integrators in automated manufacturing, a failed 3HAC6157-1 drive module can halt an entire production cell, making it a high-priority spare part. The performance and reliability of this module directly dictate the accuracy, speed, and smoothness of the robot’s movement.

Product Parameters

- Component Type: Drive Module / Axis Control Board (for ABB Robots).

- Product Family: ABB Robot Drives (part of the Drive Module assembly for specific robot models).

- Part Number: 3HAC6157-1.

- Compatibility: Designed for specific ABB robot models and controller generations (e.g., IRC5 with a defined Drive Module type). It is not universal across all robots.

- Controlled Axis: Typically controls one specific robot axis (e.g., axis 1, 2, or 3) or a group of axes, depending on the robot’s drive architecture.

- Communication: Connects to the robot controller via a high-speed internal fieldbus (e.g., Drivelink/Dispatch Bus).

- Feedback Interface: Interfaces with the motor’s feedback device (resolver or absolute encoder) for precise position and speed control.

- Safety Integration: Contains circuitry related to SafeMove safety functions, monitoring motor brakes and enabling safe torque off (STO).

- Form Factor: A printed circuit board (PCB) that is part of a larger, modular Drive Module unit within the robot controller cabinet.

Advantages and Features

- Deterministic High-Performance Control: Provides the processing power and algorithms necessary for the dynamic, high-accuracy motion required in applications like arc welding, material handling, and machining.

- Integrated Safety Functions: Works in conjunction with ABB’s SafeMove to enable functional safety directly at the drive level, allowing for speed and position monitoring for safe human-robot collaboration (HRC) scenarios.

- Advanced Diagnostics: The module is continuously monitored by the robot controller. Detailed fault codes and drive status are available in the robot’s FlexPendant or service software, enabling precise troubleshooting.

- Optimized for Robotic Motion: The control algorithms are specifically tuned for robotic arm dynamics, managing inertia, friction, and gravity compensation for optimal path accuracy.

- Modular Serviceability: As part of ABB’s modular drive system, a faulty 3HAC6157-1 board can often be replaced without swapping the entire power amplifier or drive module, reducing repair time and cost.

Application Cases in Application Fields

- Automotive Manufacturing (Spot Welding): Controlling the precise movement of a heavy spot welding gun attached to an IRB 6700 robot, ensuring each weld is made at the exact programmed location.

- Metal Fabrication (Plasma/Laser Cutting): Providing the smooth, high-speed motion control for a robot manipulating a cutting torch along a complex contour.

- Packaging & Palletizing: Driving the fast and repetitive axis movements of a palletizing robot (e.g., IRB 660) that picks and places boxes onto a pallet.

- Foundries (Die Casting): Controlling the robot extracting hot parts from a die-casting machine, where reliable motion under high thermal stress is critical.

Comparisons with Competing Products

The ABB 3HAC6157-1 is a proprietary robot component. Its functional competitors are axis control modules from other industrial robot manufacturers:

- Fanuc Servo Amplifier (e.g., A06B- series): Performs a similar function for Fanuc robots. The 3HAC6157-1 is distinguished by its deep integration with ABB’s robot software and safety architecture.

- KUKA KSD (Kuka Servo Drive): The KUKA equivalent. The ABB module’s advantage lies within the ecosystem of ABB’s calibration and service tools.

- Yaskawa (Motoman) Servopacks: For Yaskawa robots.

There is no cross-compatibility. The key advantage of the genuine ABB 3HAC6157-1 is guaranteed performance, safety certification, and support within the ABB robot system. Using a non-genuine or incorrectly matched drive board can lead to erratic motion, loss of accuracy, safety system faults, and void the robot’s warranty.

Selection Suggestions and Precautions

- Absolute Robot Model Matching: This is critical. The 3HAC6157-1 part number is specific to certain robot models and controller configurations. You must verify the exact part number from the robot’s spare parts manual or the label on the failed board. Using the wrong board can cause severe damage.

- Controller Synchronization (Calibration): After replacing a drive module, the robot will require a revolution counter update (often called “calibration” or ” mastering”). This is a mandatory procedure to teach the controller the exact mechanical position of each axis. It requires a FlexPendant and proper calibration tools (e.g., a calibration rig or EMT kit).

- Electrostatic Discharge (ESD) Protection: Handle the board as a sensitive electronic component. Use an ESD wrist strap and grounded mat.

- Professional Service Recommended: Replacement involves working inside the robot controller cabinet with hazardous voltages. This task should be performed by ABB-certified personnel or highly trained technicians following lock-out/tag-out (LOTO) procedures.

- Software Backup and Restoration: Before replacement, back up the robot system (including all parameters and programs). After installation and calibration, you may need to restore parameters or update the drive module’s firmware.

XT375a-E ABB PLC

XB8971b ABB PLC

XB8970a ABB

XB381a ABB

XB370a ABB PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922