Description

Product Overview and Description

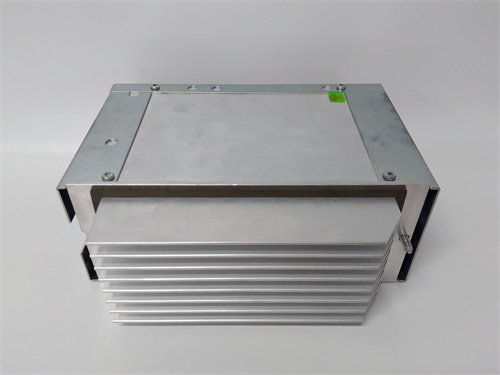

The ABB 3HAB8101-18/09A is a specialized power supply module for the ABB IRB 6000 series of industrial robots. This critical component functions as the primary DC power converter within the robot controller cabinet, taking the incoming three-phase AC mains voltage and converting it into the stable, regulated DC bus voltage required by the robot’s axis drives and internal electronics. The ABB 3HAB8101-18/09A ensures that the robot’s servo motors receive consistent and clean power, which is fundamental for achieving precise motion, repeatable positioning, and overall system reliability.

Product Parameters

- Module Type: Robot Controller DC Power Supply Unit (PSU).

- Compatibility: ABB IRB 6000 Series Robot Controllers (e.g., S4C, S4Cplus, IRC5 systems for the 6000 series).

- Input Power: Three-phase AC input. The specific voltage (e.g., 400V AC, 480V AC) and frequency (50/60 Hz) are defined by the variant code (“-18/09A”).

- Output: Provides a regulated high-voltage DC bus (typically in the range of 600-800 V DC) to power the Drive Module which controls the servo motors.

- Function: Converts AC to DC, provides inrush current limiting, and includes necessary filtering to meet electromagnetic compatibility (EMC) standards.

- Protections: Includes safety circuits and diagnostics for overvoltage, undervoltage, overcurrent, and overtemperature conditions.

- Cooling: Typically uses forced air cooling via an integrated fan.

- Form Factor: Designed to mount on the chassis or backplane of the specific robot controller cabinet.

- Communication: May provide status signals to the robot’s main computer module via internal connectors.

Advantages and Key Features

- Robust and Reliable Power Delivery: The ABB 3HAB8101-18/09A is engineered for the demanding duty cycles of industrial robotics, providing stable DC power that is critical for maintaining servo motor torque and preventing motion faults during high-speed or high-payload operations.

- Optimized for ABB Drive Systems: This power supply is specifically designed to match the electrical characteristics and power requirements of the associated ABB Drive Module in the same controller, ensuring optimal performance and protecting the expensive drive and motor components.

- Integrated Safety and Diagnostics: Built-in protection circuits safeguard the robot system from electrical faults, while diagnostic outputs allow the main controller to monitor the health of the ABB 3HAB8101-18/09A, enabling predictive maintenance and reducing unplanned downtime.

- Compact and Integrated Design: As an original ABB component, it fits perfectly into the designated slot in the controller cabinet, ensuring proper airflow, electrical connections, and mechanical stability.

- Proven Performance in Harsh Environments: Designed to operate reliably in typical factory conditions with vibration, dust, and variable temperatures, contributing to the overall robustness of the robot system.

Application Cases in Various Fields

- Automotive Spot Welding: Providing the high, consistent power needed for the rapid, high-torque movements of a large IRB 6000 robot performing spot welding on a car body-in-white assembly line.

- Material Handling & Machine Tending: Powering robots that load/unload heavy castings from CNC machines or palletize finished goods, where reliable power is needed for precise lifting and placement cycles.

- Die Casting: Operating in a demanding foundry environment to extract hot parts from dies, where the ABB 3HAB8101-18/09A ensures the robot can perform reliably despite heat and particulate contamination.

- Heavy Assembly: Enabling the powerful and precise motions required for assembling large components in the construction equipment or agricultural machinery industry.

Comparison with Competing Products

The ABB 3HAB8101-18/09A is an OEM-specific part. Competing products would be the power supply units inside robot controllers from other manufacturers like Fanuc, KUKA, or Yaskawa Motoman. Compared to a generic industrial power supply, it is mechanically and electrically customized for its specific robot controller frame. Its primary advantage is guaranteed compatibility, performance, and safety certification within the ABB robot ecosystem. Attempting to use a non-genuine or third-party power supply in an ABB controller risks improper operation, voided warranties, and potential safety hazards due to mismatched electrical characteristics or lack of proper diagnostic integration.

Selection Suggestions and Precautions

- Selection Advice:

- Exact Robot Model Match: This part number is specific to certain IRB 6000 robot models and controller generations (S4C/S4Cplus). Verify the exact controller type and robot serial number to ensure compatibility before ordering.

- Input Voltage Verification: The suffix (“-18/09A”) encodes the input voltage rating. Ensure this matches the plant’s mains supply voltage (e.g., 400V vs. 480V). Using an incorrect voltage unit will cause failure.

- Diagnose Before Replacement: A power supply fault often manifests as a main contactor failure or DC bus under-voltage alarm. Use the robot’s diagnostic system to confirm the ABB 3HAB8101-18/09A is the root cause before replacement.

- Important Precautions:

- High-Voltage Hazard: The module contains lethal AC input and high-voltage DC bus capacitors that can remain charged long after power is disconnected. Only qualified electricians should perform removal/installation, following lockout/tagout procedures.

- Electrostatic Discharge (ESD): Handle the module as an ESD-sensitive device.

- Cooling System Integrity: Before installing a new or refurbished unit, ensure the controller cabinet’s cooling fans and filters are clean and functional. Overheating is a common cause of power supply failure.

- Configuration and Calibration: Replacement of this module in an IRC5 system may require the robot to relearn its absolute accuracy calibration (QuickMove or Absolute Accuracy). Consult the robot’s maintenance manual.

- Use Genuine ABB Parts: For safety, reliability, and to maintain the robot’s performance specifications, always use a genuine or ABB-certified refurbished ABB 3HAB8101-18/09A. Counterfeit parts pose significant risks.

- Dispose Properly: Follow local regulations for the disposal of electronic waste. The unit may contain components that require special handling.

1C31169G01 PLC

1C31174G01 EMERSON

1C31174G02 PLC EMERSON

1C31174G03 PLC EMERSON

1C31174G04

1C31177G01 PLC

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922