Description

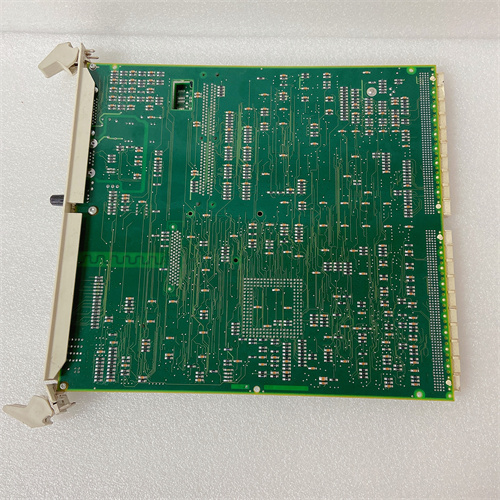

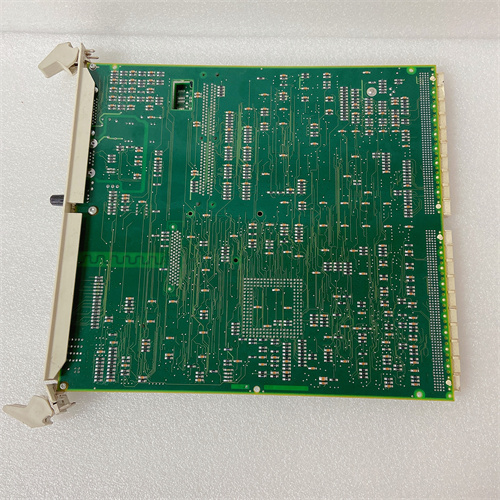

ABB 3BSE011180R1 SE04462912 PM511V08 – PLC Automation Core Controller

ABB 3BSE011180R1 SE04462912 PM511V08 is a high-performance modular PLC controller belonging to ABB’s AC 500 series, engineered for industrial automation systems requiring reliable, real-time control and seamless integration with industrial field devices. As a core component of ABB’s low-to-medium range automation solutions, ABB 3BSE011180R1 SE04462912 PM511V08 combines compact design with robust processing capabilities, making it a staple in discrete manufacturing, process control, and building automation applications worldwide.

Product Description

ABB 3BSE011180R1 SE04462912 PM511V08 is a CPU module for the AC 500 PLC platform, featuring a 32-bit processor with optimized instruction execution speed to handle complex logic control, data acquisition, and communication tasks with minimal latency. The module supports a wide range of I/O expansions via ABB’s proprietary bus system, allowing users to scale their automation setups from small standalone systems to large distributed control networks. ABB 3BSE011180R1 SE04462912 PM511V08 integrates non-volatile memory for program and data storage, eliminating the need for external backup batteries and reducing maintenance requirements in harsh industrial environments. It also features built-in diagnostic functions that provide real-time status feedback, enabling quick troubleshooting and minimizing unplanned downtime for industrial operations.

Product Parameters

- Processor: 32-bit RISC core, operating frequency optimized for industrial control

- Memory: 256 KB program memory, 128 KB data memory (non-volatile)

- I/O Capacity: Supports up to 2048 digital I/O or 256 analog I/O points via AC 500 I/O modules

- Communication Interfaces: Built-in RS-485 (Modbus RTU/Profibus DP), optional Ethernet (TCP/IP) expansion

- Power Supply: 24 V DC (19.2 – 28.8 V DC), reverse polarity protection

- Operating Temperature: -20 °C to +60 °C, wide temperature tolerance for industrial sites

- Isolation: Reinforced electrical isolation between I/O, communication and power circuits

- Mounting: DIN rail mounting (35 mm), compact form factor for panel space optimization

- Certifications: CE, UL, ATEX, IEC 61131-3 compliant for global industrial use

- Cycle Time: <1 ms for 1k boolean instructions, fast real-time response

Advantages and Features

- Robust Industrial Design: ABB 3BSE011180R1 SE04462912 PM511V08 is built with industrial-grade components, resistant to vibration, shock, and electrical interference, meeting the strict environmental requirements of factory floors, power plants, and outdoor industrial installations.

- Seamless ABB Ecosystem Integration: The module works natively with ABB’s AC 500 I/O modules, HMI panels, and drive systems, creating a unified automation solution with no compatibility gaps and simplified system configuration.

- IEC 61131-3 Programming Compliance: Supports all standard IEC 61131-3 programming languages (LD, FBD, ST, IL, SFC), enabling flexible programming by engineers with different technical backgrounds and easy code portability across projects.

- Low Maintenance Operation: Non-volatile memory and battery-free design eliminate common maintenance tasks, while built-in self-diagnostics reduce the need for manual system checks and speed up fault resolution.

- Scalable Performance: The modular architecture allows users to add I/O, communication, or functional modules as their automation needs grow, making ABB 3BSE011180R1 SE04462912 PM511V08 a cost-effective long-term solution for evolving industrial systems.

- Global Certification Compliance: Meets international safety and EMC standards, enabling direct deployment in European, North American, and Asian markets without additional certification modifications.

Application Fields & Application Cases

Core Application Fields

- Discrete manufacturing (automotive assembly, packaging machinery, material handling systems)

- Process control (water/wastewater treatment, chemical processing, food and beverage production)

- Building automation (HVAC control, lighting management, access control systems)

- Power distribution and renewable energy (solar/wind farm auxiliary control, substation monitoring)

- Marine and offshore (small-scale vessel automation, onshore support equipment control)

Typical Application Cases

- Food and Beverage Production Line: A European food processing plant implemented ABB 3BSE011180R1 SE04462912 PM511V08 as the main controller for a beverage filling and packaging line. The module’s fast cycle time ensured precise synchronization of filling, capping, and labeling processes, while its resistance to moisture and temperature fluctuations met the plant’s hygienic and industrial environmental requirements. The integration with ABB’s AC 500 I/O modules enabled real-time monitoring of production speed and product quality, increasing line efficiency by 15%.

- Water Treatment Plant: A municipal wastewater treatment plant in Asia used ABB 3BSE011180R1 SE04462912 PM511V08 to control pump stations, aeration systems, and chemical dosing units. The module’s Modbus and Profibus communication capabilities allowed seamless connection to remote monitoring systems, while its wide temperature tolerance ensured reliable operation in outdoor pump houses. The built-in diagnostic functions reduced equipment downtime by 20% by alerting maintenance staff to potential pump and valve faults before they caused system failures.

- Packaging Machinery Automation: A North American packaging equipment manufacturer integrated ABB 3BSE011180R1 SE04462912 PM511V08 into its high-speed cartoning machines. The module’s scalable I/O capacity supported the integration of sensors, actuators, and vision inspection systems, while its IEC 61131-3 compliance allowed the manufacturer to quickly customize control logic for different customer packaging requirements, reducing machine design and commissioning time by 25%.

Comparison with Competing Products

| Aspect | ABB 3BSE011180R1 SE04462912 PM511V08 | Competitor 1 (Siemens S7-1200 CPU 1214C) | Competitor 2 (Schneider Modicon M340 CPU340-20) |

|---|---|---|---|

| Ecosystem Integration | Native integration with ABB drives, HMIs, and I/Os; unified system design | Good integration with Siemens SIMATIC products; limited third-party compatibility | Seamless Schneider EcoStruxure integration; moderate ABB device compatibility |

| Temperature Tolerance | -20 °C to +60 °C (wider industrial range) | 0 °C to +55 °C (indoor/protected use only) | -10 °C to +55 °C (enhanced but narrower than ABB) |

| Memory Configuration | 256 KB program / 128 KB data (non-volatile, battery-free) | 1 MB program / 1 MB data (battery-backed for data retention) | 512 KB program / 256 KB data (battery-free) |

| I/O Scalability | Up to 2048 digital I/O (AC 500 modules) | Up to 1024 digital I/O (SM 1200 modules) | Up to 1600 digital I/O (BMX I/O modules) |

| Industrial Certifications | ATEX, marine certification options | Basic CE/UL; limited hazardous area certs | CE/UL; ATEX for selected models |

Key Competitive Edge: ABB 3BSE011180R1 SE04462912 PM511V08 stands out for its wider operating temperature range, battery-free non-volatile memory, and seamless integration with ABB’s industrial drive and HMI products—critical advantages for industrial applications in harsh environments or those requiring a unified automation ecosystem. It also offers more flexible hazardous area certification options than mid-range competitors, making it suitable for process control and marine applications.

Selection Suggestions

- System Scale Matching: Choose ABB 3BSE011180R1 SE04462912 PM511V08 for automation systems with 500–2000 digital I/O points or 50–256 analog I/O points; for smaller systems (<500 I/O), opt for a compact ABB AC 500-eCo CPU, and for larger systems (>2000 I/O), upgrade to ABB PM554/PM564 CPUs.

- Environmental Considerations: Prioritize ABB 3BSE011180R1 SE04462912 PM511V08 for outdoor, high-vibration, or wide-temperature industrial sites (e.g., mining, renewable energy, marine) due to its robust industrial design and wide temperature tolerance.

- Ecosystem Compatibility: Select this module if your automation setup already uses ABB drives (ACS series), HMI panels (CP600/CP700), or I/O modules, as it eliminates compatibility issues and simplifies system programming and commissioning.

- Communication Requirements: If your system needs Profibus DP/Modbus RTU as the primary communication protocol, ABB 3BSE011180R1 SE04462912 PM511V08 is a direct fit; for Ethernet/IP or PROFINET dominance, add an ABB Ethernet expansion module to the unit.

Precautions

- Power Supply Installation: Ensure the power supply is 24 V DC (19.2–28.8 V DC) with stable voltage; avoid overvoltage/undervoltage, and use surge protection devices in areas with unstable power grids to prevent damage to ABB 3BSE011180R1 SE04462912 PM511V08.

- Wiring and Isolation: Follow ABB’s wiring specifications for communication and I/O circuits; maintain proper electrical isolation between high-voltage and low-voltage lines to avoid electromagnetic interference that may affect the module’s performance.

- Program Storage and Backup: While the module has non-volatile memory, regularly back up control programs to an external storage device (e.g., ABB SD card) to prevent program loss due to extreme physical damage.

- Mounting and Ventilation: Mount ABB 3BSE011180R1 SE04462912 PM511V08 on a 35 mm DIN rail with adequate ventilation space (minimum 50 mm on all sides) to prevent overheating; avoid mounting in direct sunlight or near heat-emitting equipment (e.g., drives, heaters).

- Commissioning and Testing: Conduct full system testing (logic control, data acquisition, communication) after installation; use ABB’s CoDeSys-based AC 500 programming software to run diagnostic tests and verify all I/O and communication functions before full industrial operation.

- Replacement and Maintenance: When replacing the module, power off the entire AC 500 system first; ensure the replacement unit is the same model (ABB 3BSE011180R1 SE04462912 PM511V08) for direct compatibility, and re-upload the control program and parameter settings after replacement.

- Certification Compliance: Ensure the module is used in accordance with its CE/UL/ATEX certifications; do not deploy it in hazardous areas beyond its certified rating (e.g., explosive gas zones without additional ATEX protection).

IS200BLIGH1A GE

3BSE018876R1 PFSK151 PLC

IS200CABPG1B GE PLC

IS200CPFPG1A GE PLC

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922