Description

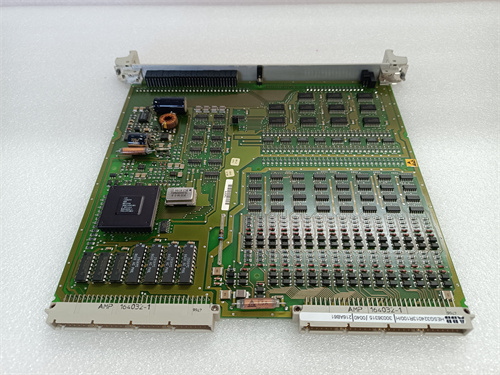

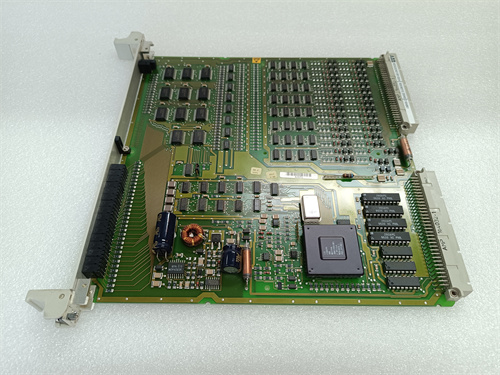

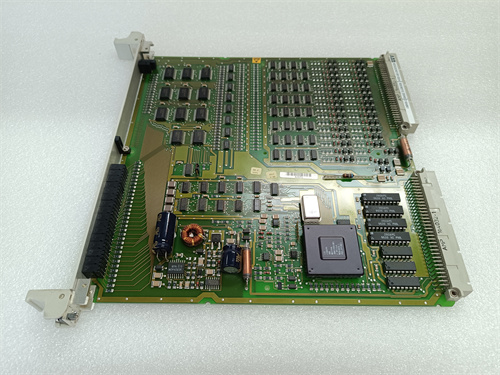

Product Overview: ABB 216AB61

ABB 216AB61 is a core component in industrial automation and discrete process monitoring, serving as an original discrete input module under the ABB brand. It is specifically designed for high-reliability scenarios such as energy, heavy industry, and infrastructure, seamlessly integrating with PLC control systems like the ABB AC 800M Distributed Control System (DCS) and ABB Ability™ System 800xA integrated automation platform. Whether deployed in auxiliary control of thermal power plants, production line monitoring in steel mills, or conveyor systems in logistics warehouses, ABB 216AB61 maintains accurate discrete signal acquisition even in harsh industrial environments with dust, temperature fluctuations, or electromagnetic interference. Access to the product link ([Insert official link for ABB 216AB61 here]) provides comprehensive technical documentation, including IEC 61131-2 compliance certificates and installation guides—critical support for engineers to ensure ABB 216AB61 integrates smoothly with existing PLC architectures and avoids signal acquisition interruptions.

Technical Parameters: ABB 216AB61

The technical characteristics of ABB 216AB61 ensure high stability and adaptability in discrete signal acquisition scenarios, with key parameters as follows:

- Module Type: 16-channel isolated discrete input module, supporting 24V DC standard industrial signals. The logic level range is “0” (0–5V DC) and “1” (15–24V DC), compatible with photoelectric sensors, safety interlocks, pushbuttons, and other discrete devices, meeting multi-scenario signal acquisition needs.

- Channel Isolation: Isolation voltage between channels is 250V AC (for 1 minute), and between channels and ground is 500V AC (for 1 minute). This effectively blocks cross-channel electromagnetic interference and prevents ABB 216AB61 from damage due to sensor circuit faults, ensuring signal accuracy.

- Operating Environment: Temperature range of -40°C to +70°C, enabling stable operation in extreme environments such as outdoor substations and high-temperature workshops. Electromagnetic interference (EMI) resistance complies with the IEC 61000-6-2 industrial standard, unaffected by interference from high-power motors or transformers.

- Power Supply & Consumption: Supports 24V DC power supply (with ±10% voltage fluctuation tolerance) and has a maximum power consumption of only 3.2W. It can be directly connected to the standard power circuit of PLC systems without additional power modules, reducing system deployment costs.

- Response Time: Signal response time ≤ 1ms, quickly capturing sensor state changes (e.g., missing materials on conveyors, door switch actions). This ensures the PLC controller triggers linked controls (e.g., emergency shutdowns, alarm outputs) promptly to avoid production accidents.

- Protection Rating: The module itself has an IP20 protection rating. It is recommended to install it in control cabinets with IP54 or higher protection to prevent dust and moisture from damaging the internal circuits of ABB 216AB61 and extend its service life.

Complete parameters can be found via the ABB 216AB61 product link ([Insert link here]), which includes detailed electrical characteristics and environmental adaptability test data.

Advantages and Features: ABB 216AB61

Compared with similar discrete input modules, ABB 216AB61 stands out as a preferred choice for industrial scenarios due to the following core advantages:

- Full-Scenario Compatibility: It not only integrates seamlessly with ABB’s own AC 800M and System 800xA controllers but also supports third-party PLC systems (e.g., Siemens SIMATIC, Rockwell Allen-Bradley) via standard protocols. Upgrades can be completed without replacing existing hardware, reducing enterprise transformation costs.

- High-Reliability Design: In addition to channel isolation, ABB 216AB61 uses industrial-grade anti-aging components (e.g., high-temperature-resistant capacitors, gold-plated contacts). It can operate stably continuously for 12–15 years in -40°C to +70°C environments—far longer than the industry average of 8–10 years—reducing downtime for maintenance.

- Convenient Diagnostics & Maintenance: Each channel is equipped with an independent LED status indicator: a green light indicates normal signals, and a red light alerts to channel faults (e.g., sensor disconnection, short circuit). Engineers can quickly locate issues without disassembling the module. It also supports remote fault early warning by reading module self-test data via the PLC system.

- Compact Installation: With a height of only 120mm, the module can be directly mounted on standard DIN rails. It can be densely arranged in control cabinets, making it ideal for small control boxes with limited space (e.g., local control units for logistics sorting lines) and improving cabinet space utilization.

Application Cases: ABB 216AB61

Thanks to its stability and adaptability, ABB 216AB61 is widely used in key links across multiple industries:

- Heavy Industry: In the hot rolling production line of a steel mill, ABB 216AB61 collects signals from billet positioning sensors and roller table safety interlocks. If billet deviation or unclosed interlocks are detected, it immediately sends signals to the PLC to trigger roller table shutdown, preventing equipment collisions or personnel injuries.

- Energy Industry: In the box-type substation of a wind farm, ABB 216AB61 monitors circuit breaker status and cabinet door switch signals. If abnormal circuit breaker tripping or unauthorized cabinet door opening is detected, it can quickly link the PLC to cut off the high-voltage circuit, preventing power grid fluctuations or electric shock accidents.

- Logistics & Warehousing: In the conveyor system of an automated stereoscopic warehouse, ABB 216AB61 receives “goods in place” signals from photoelectric sensors and trigger signals from emergency stop buttons, enabling precise start/stop of conveyors and fault emergency shutdowns to ensure sorting efficiency and operational safety.

- Food Processing: In a beverage filling production line, ABB 216AB61 collects signals from bottle detection sensors and filling valve statuses. If missing empty bottles or unclosed valves are detected, it immediately pauses the filling process to avoid raw material waste and prevent non-conforming products from entering the market.

Comparison with Competitors: ABB 216AB61

A comparison of ABB 216AB61 with two mainstream similar modules (Brand X’s Module XX and Brand Y’s Module YY) highlights its clear advantages:

| Comparison Dimension | ABB 216AB61 | Brand X Module XX | Brand Y Module YY |

|---|---|---|---|

| Number of Channels & Isolation | 16 channels, fully isolated | 12 channels, no isolation | 14 channels, partially isolated |

| Response Time | ≤1ms | ≤2ms | ≤1.5ms |

| Operating Temperature Range | -40°C ~ +70°C | -30°C ~ +65°C | -25°C ~ +60°C |

| EMI Resistance Level | IEC 61000-6-2 (Industrial) | Basic protection only | IEC 61000-6-3 (Civilian) |

| Design Service Life | 12–15 years | 7–8 years | 8–10 years |

As shown in the table, ABB 216AB61 outperforms competitors in channel configuration, environmental adaptability, and reliability, making it particularly suitable for critical industrial scenarios with high stability requirements.

Selection Recommendations and Usage Precautions

Selection Recommendations

- Confirm Signal Requirements: If 12–16 channels of 24V DC discrete signals (e.g., sensors, pushbuttons) need to be collected, ABB 216AB61 is the optimal choice. For fewer channel needs (8 or fewer), ABB’s 8-channel modules in the same series can be used, but ABB 216AB61 offers better cost-effectiveness for future expansion.

- Adapt to Environmental Conditions: For outdoor or high-temperature workshops (e.g., metallurgy, chemical engineering), prioritize ABB 216AB61. For ordinary room-temperature workshops (e.g., electronics assembly), competitors may be an option, but the redundant design of ABB 216AB61 reduces long-term operational risks.

- Check System Compatibility: If the existing PLC is an ABB brand, ABB 216AB61 can be used for “plug-and-play” integration. For third-party systems, confirm protocol compatibility via the product link ([Insert ABB 216AB61 link here]) or consult ABB technical support for configuration solutions.

Usage Precautions

- Avoid Over-Parameter Operation: Do not connect voltages exceeding 24V DC to the input channels of ABB 216AB61, and control the sensor circuit current within the module’s allowable range (maximum 50mA/channel). Otherwise, internal circuits may be burned.

- Standardize Installation & Maintenance: The module must be installed in a control cabinet with IP54 or higher protection. Reserve a 5–10mm heat dissipation gap during installation. Check terminal tightness and LED indicator status every 6 months to avoid signal loss due to poor contact.

- Use Original Accessories: When repairing, replace components (e.g., terminal blocks, fuses) with ABB original parts. Non-original accessories may have mismatched sizes or substandard materials, leading to abnormal operation of ABB 216AB61 or shortened service life.

216AB61

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: jiedong@sxrszdh.com

Email: jiedong@sxrszdh.com Phone / Wechat:+86 15340683922

Phone / Wechat:+86 15340683922

Wechat:+86 15343416922

Wechat:+86 15343416922