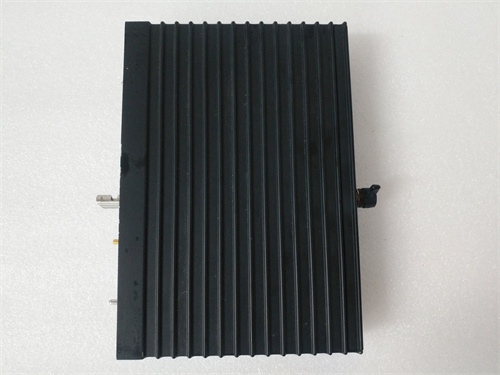

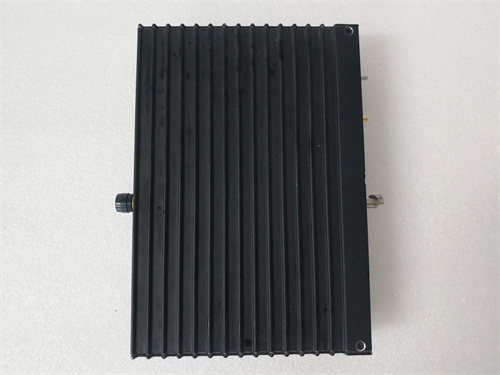

Product Name

TRICONEX 3401

Product Description

The TRICONEX 3401 is a high-performance programmable logic controller (PLC) designed for critical and safety applications in various industrial environments. This robust controller offers exceptional reliability and flexibility, making it an excellent choice for processes that require stringent safety measures and operational efficiency. With its advanced functionality, the TRICONEX 3401 enables organizations to enhance productivity while simultaneously maintaining compliance with safety standards.

Product Specifications

- Architecture: Redundant configuration for high availability

- Input/Output: Supports a wide range of input and output types

- Programming Language: IEC 61131-3 compliant

- Performance: High-speed processing capabilities

- Communication Protocols: Supports multiple industrial communication protocols

- Operating Temperature: -20°C to 60°C

- Power Supply: Suitable for various power supply specifications

Advantages and Features

The TRICONEX 3401 stands out due to its following advantages and features:

- Safety Assurance: Designed for safety-critical systems, ensuring high integrity and reliability.

- Scalability: Easily scalable architecture allows for integration into existing systems.

- User-Friendly: Intuitive programming and configuration interfaces streamline the setup process.

- Flexibility: Versatile input/output options cater to diverse operational requirements.

- Redundancy: Enhanced redundancy features ensure continuous operations and minimize downtime.

Application Fields and Case Studies

The TRICONEX 3401 is widely utilized in various industries including:

- Oil and Gas: Used for process control and safety systems in upstream, midstream, and downstream operations.

- Chemical Processing: Manages complex chemical processes while adhering to safety regulations.

- Power Generation: Streamlines operations in power plants, enhancing system reliability and safety.

- Water and Wastewater Management: Controls critical processes to promote environmental safety and compliance.

For instance, in a large chemical processing plant, the TRICONEX 3401 was implemented to manage the safety interlocks and emergency shutdown procedures, drastically reducing accident risks and improving overall plant efficiency.

Competitive Comparison

When compared to other PLC models such as Siemens S7-1500 and Rockwell ControlLogix, the TRICONEX 3401 offers superior scalability and safety features specifically designed for critical environments. While the Siemens S7-1500 focuses on high-performance standard applications, and Rockwell ControlLogix provides strong integration capabilities for general automation, the TRICONEX 3401 excels in environments where safety and reliability are paramount.

Selection Recommendations

When choosing the TRICONEX 3401, consider factors such as:

- Application Requirements: Ensure the specifications match your project’s safety and control needs.

- Integration: Assess compatibility with existing systems and protocols in use.

- Future Needs: Choose a model that allows for scalability as your operations evolve.

Precautions

It is important to keep the following in mind when working with the TRICONEX 3401:

- Regular Maintenance: Schedule periodic checks to ensure all components are functioning optimally.

- Firmware Updates: Keep the device’s firmware up to date to access the latest features and security enhancements.

- Training: Ensure operators and maintenance personnel are adequately trained to use and troubleshoot the PLC effectively.

We are your trusted partner, providing sales and technical support for the TRICONEX 3401 and other automation spare parts. Special discount pricing is available. Please contact us, and we will be dedicated to serving you.

TRICONEX 3401