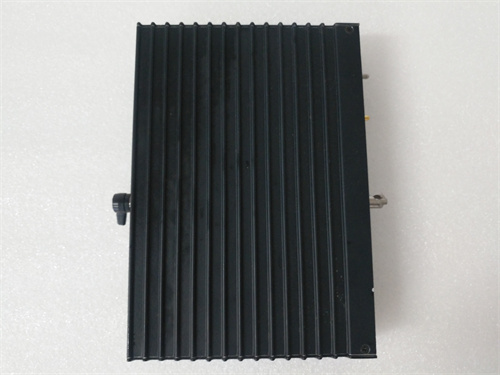

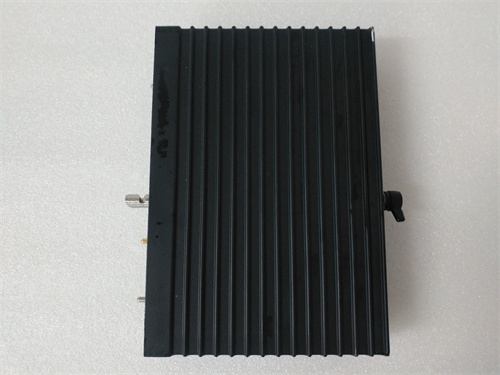

Product Name

TRICONEX 3301

Product Description

The TRICONEX 3301 is a highly reliable and advanced controller utilized in various automated systems. Manufactured by Triconex, a leader in safety instrumented systems, the TRICONEX 3301 is designed to enhance the safety and efficiency of industrial processes. This model is part of the renowned Triconex safety system, known for its fault-tolerant architecture and redundancy features, making it ideal for mission-critical applications.

The TRICONEX 3301 controller excels at monitoring and controlling various industrial processes. With its robust construction, it can withstand harsh operating conditions, ensuring optimal performance in challenging environments. Featuring a user-friendly interface, the TRICONEX 3301 simplifies the programming and maintenance tasks, allowing operators to focus on core functions without the hassle of complex configurations.

Product Specifications

- Operating Voltage: 24 VDC

- Communication Protocols: Modbus, TCP/IP, and various serial protocols

- Input/Output Capacity: Supports up to 256 digital and analog I/O

- Temperature Range: -10°C to 60°C

- Mounting Type: DIN rail or panel mounting

- Dimensions: Compact design for easy integration into existing systems

Advantages and Features

The TRICONEX 3301 offers several significant advantages and features, including:

- Fault Tolerance: The system is designed to operate continuously, even in the event of hardware or software failures, ensuring maximum uptime.

- Scalability: The TRICONEX 3301 can be easily scaled to meet the growing demands of industrial applications.

- User-Friendly Interface: Its intuitive design simplifies operation, allowing quick configuration and troubleshooting.

- Regulatory Compliance: Meets various industry standards for safety and performance, making it suitable for diverse applications.

Application Areas and Case Studies

The TRICONEX 3301 is widely applied across various sectors, including:

- Oil and Gas: For controlling and monitoring critical processes such as drilling and refining.

- Manufacturing: In automation of assembly lines and quality control systems.

- Power Generation: Employed in the management of power plants and substations.

- Water Treatment: Used in the regulation of wastewater treatment processes.

One notable case study involves a major oil refining company that implemented the TRICONEX 3301 for its critical safety instrumented functions. The seamless integration and reliability of this controller resulted in improved safety measures and reduced downtime, enhancing overall production efficiency.

Competitive Product Comparison

When compared to other PLCs in the market, the TRICONEX 3301 stands out due to its combination of safety and reliability. While competitors like Siemens and Allen-Bradley offer robust solutions, the fault-tolerant design and specialized safety features of the TRICONEX 3301 make it as a top choice for safety-critical applications.

Selection Suggestions

When selecting the TRICONEX 3301, consider the following aspects:

- Application Needs: Assess whether your application requires a high level of safety and reliability.

- System Integration: Ensure compatibility with existing systems and protocols.

- Scalability Requirements: Evaluate future expansion possibilities to make an informed decision.

Precautions

When working with the TRICONEX 3301, keep in mind:

- Follow installation guidelines and utilize the appropriate mounting equipment.

- Regularly perform maintenance checks to ensure continued performance.

- Stay updated with firmware and software upgrades provided by Triconex for optimal operation.

We are your trusted partner, providing sales and technical support for TRICONEX 3301 and other automation spare parts. Enjoy special discounted prices by contacting us, and we will be dedicated to serving you.

TRICONEX 3301