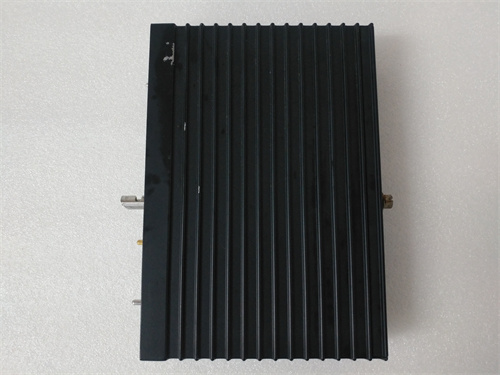

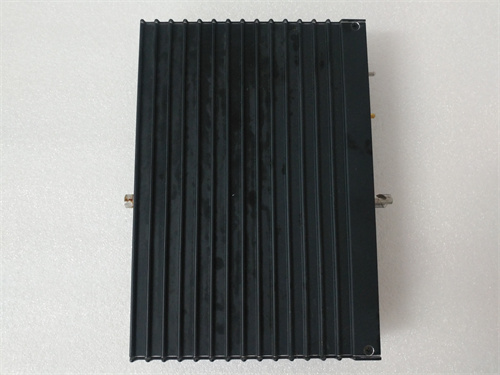

Product Name

Triconex 3201

Product Description

The Triconex 3201 is a reliable and robust safety controller designed for critical process control and safety applications. As part of the Triconex product line, the 3201 provides a fault-tolerant architecture that ensures high availability and safety in demanding environments. This makes it ideal for industries such as oil and gas, chemical manufacturing, and power generation. The Triconex 3201 integrates seamlessly with various field devices and other control systems, facilitating optimal performance and safety management in operational processes.

Product Specifications

- Model: Triconex 3201

- Type: Safety Controller

- Input Types: Digital, Analog

- Communication Protocols: Ethernet, Serial Communication

- Power Supply: 24 VDC

- Operating Temperature: -20°C to +60°C

- Mounting Type: Modular Rack System

- Safety Standards: IEC 61508, SIL 3 Certified

Advantages and Features

The Triconex 3201 comes equipped with several advantages:

- High Reliability: Designed with redundancy in mind, ensuring uninterrupted service.

- Flexible Architecture: Supports multiple input and output types, accommodating various application needs.

- Comprehensive Diagnostics: Built-in self-diagnosis features enhance maintenance and troubleshooting efficiency.

- Scalability: Easily scalable to meet growing demands or upgrade needs.

- Industry Compliance: Certified for high safety standards, ensuring compliance with regulatory requirements.

Application Fields and Case Studies

The Triconex 3201 is widely used in critical applications:

- Oil and Gas: Used for wellhead control systems and emergency shutdown systems.

- Chemical Processing: Integration in hazardous material handling to mitigate risks.

- Power Generation: Control of safety systems in nuclear, thermal, and renewable energy facilities.

One notable case study includes the deployment of the Triconex 3201 in an offshore oil rig, where it successfully managed safety shutdown systems, significantly reducing the risk of catastrophic failures.

Competitive Comparison

When compared to competitors, such as Honeywell’s Safety Manager and Siemens’ S7-1500 series, the Triconex 3201 stands out due to its robust fault tolerance and extensive diagnostic capabilities. While others may offer competitive features, the reliability of Triconex in critical applications often provides a distinct advantage, particularly in terms of field-proven performance and safety integrity.

Selection Recommendations

When considering the Triconex 3201, take into account the specific requirements of your application, such as:

- Safety category requirements (SIL level).

- Types of inputs and outputs necessary for your system.

- Environmental factors that may influence system performance.

Ensure to evaluate compatibility with existing systems to maximize efficiency and return on investment.

Considerations

Before implementing the Triconex 3201, keep the following in mind:

- Thoroughly assess your application needs and safety requirements.

- Plan for training and support personnel to ensure effective use and maintenance.

- Regularly schedule maintenance checks to uphold system integrity and performance.

We are your trusted partner. We offer sales and technical support for the Triconex 3201 and other automation spare parts, along with special discount prices. Please contact us, and we will be happy to assist you!

TRICONEX 3201