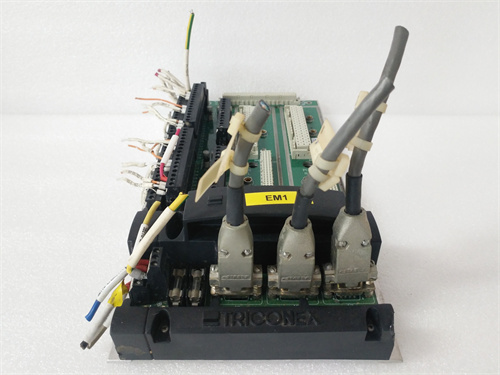

Product Name

TRICONEX 2381

Product Description

TRICONEX 2381 is a high-performance programmable logic controller (PLC) designed for critical applications in industrial automation. This controller ensures high safety and reliability, making it an ideal choice for process control systems where safety is paramount. The TRICONEX 2381 features advanced processing capabilities, extensive input/output options, and robust communication protocols to support complex automation tasks effectively.

The TRICONEX 2381 is specifically engineered to excel in demanding environments, providing exceptional fault tolerance and redundancy. With the ability to manage multiple safety functions simultaneously, the TRICONEX 2381 significantly enhances operational efficiency while maintaining rigorous safety standards.

Product Specifications

- Power Supply: 24V DC

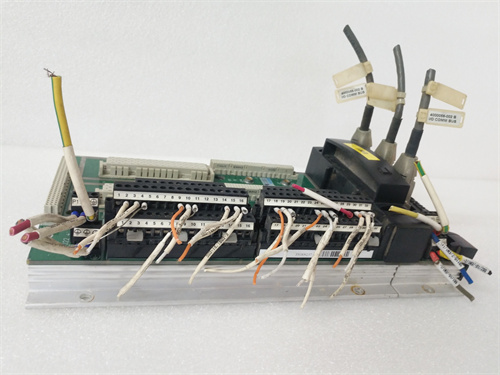

- I/O Capacity: Up to 128 digital inputs and 128 digital outputs

- Communication Ports: Ethernet, Serial, and various fieldbus options

- Operating Temperature: -20 to +60°C

- Certification: SIL 3 certified for safety integrity

- Maximum Processing Speed: 1ms per instruction

Advantages and Features

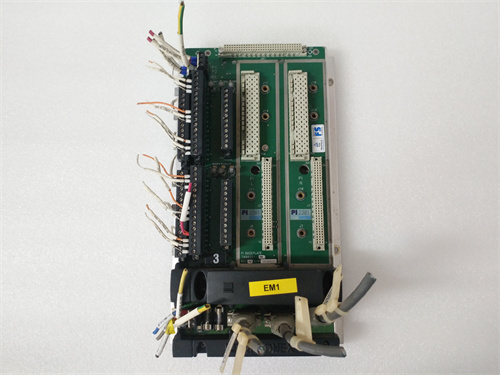

One of the standout advantages of the TRICONEX 2381 is its unparalleled reliability in safety applications. Its triple modular redundant (TMR) architecture allows for continuous operation even in the event of component failure. This makes the TRICONEX 2381 an excellent choice for industries that require stringent safety measures.

Other features include:

- Flexible I/O configurations that accommodate a wide range of devices.

- Comprehensive diagnostics and monitoring capabilities, ensuring proactive maintenance.

- User-friendly programming environments that simplify the development and deployment of automation strategies.

Applications and Use Cases

The TRICONEX 2381 is widely used across various sectors, including:

- Oil and Gas: For process control and safety systems in upstream and downstream operations.

- Chemical Manufacturing: Managing complex chemical processes with high safety requirements.

- Power Generation: Ensuring reliable control in both renewable and non-renewable energy sources.

- Water Treatment: Monitoring and controlling automated processes in water and wastewater treatment facilities.

A case study of the TRICONEX 2381 at a major oil refinery illustrates its effectiveness in automating refinery processes while meeting the stringent safety demands of the industry.

Competitive Comparison

Compared to other PLCs in the market, such as Siemens S7-1500 or Allen-Bradley ControlLogix, the TRICONEX 2381 offers unique advantages in safety-critical applications. While competitors may provide general functionality, the TRICONEX 2381 is specifically designed for high-integrity safety applications, providing SIL 3 certification that is crucial for industries such as oil, gas, and chemicals.

Selection Advice

When selecting a PLC for safety-critical applications, consider the following:

- Assess the specific safety requirements of your application and ensure compliance with industry standards.

- Look for a PLC with a proven track record in similar industries, such as the TRICONEX 2381.

- Evaluate I/O capabilities and communication protocols to ensure compatibility with existing systems.

Precautions

While the TRICONEX 2381 offers exceptional performance, it’s essential to consider environmental factors such as temperature extremes or potential electromagnetic interference that could impact operation. Proper installation and regular maintenance will ensure the longevity and reliability of the system.

We are your trusted partner providing sales and technical support for TRICONEX 2381 and other automation spare parts. We offer special discount prices for you. Please contact us; we are dedicated to serving you.

TRICONEX 2381