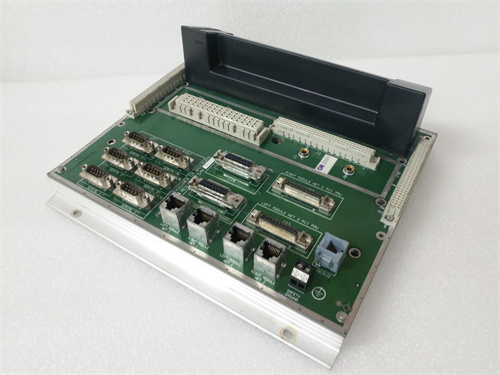

TRICONEX 2201

Product Description

TRICONEX 2201 is a high-performance programmable logic controller (PLC) specifically designed for safety and process automation in critical applications. As part of the TRICONEX safety system, the 2201 model offers robust redundancy and fault-tolerant capabilities, making it ideal for environments where safety is paramount. The TRICONEX 2201 is engineered to ensure the highest level of reliability and operational integrity, helping industries meet rigorous safety standards.

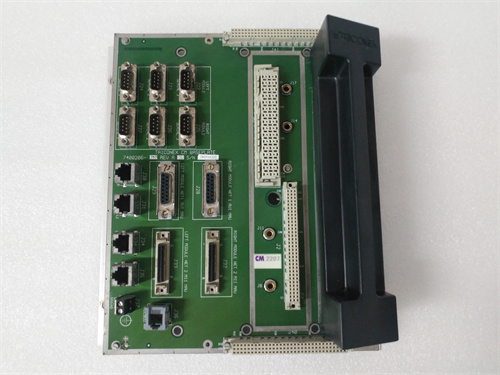

Product Specifications

- Input Voltage: 24V DC

- Current Consumption: 200 mA

- Communication Protocols: Modbus, TCP/IP

- Operating Temperature Range: -20°C to 60°C

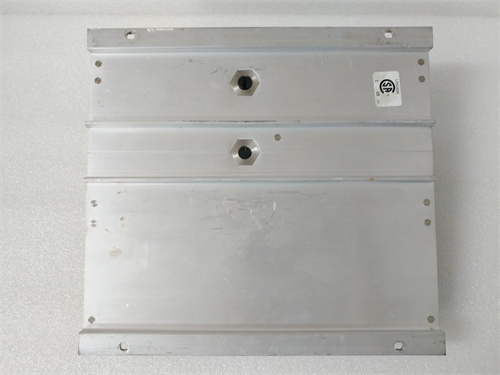

- Dimensions: 12 x 6 x 4

- Weight: 5 kg

Advantages and Features

One of the primary advantages of the TRICONEX 2201 is its capability for real-time diagnostics and monitoring, enabling rapid identification of faults and reducing downtime. Additionally, it features a user-friendly interface for easy configuration and program development. The 2201 provides extensive connectivity options, ensuring seamless integration with various field devices and systems. Its modular design allows for easy upgrades and expansions in the future.

Application Areas and Case Studies

The TRICONEX 2201 is widely used in various industries, including oil and gas, chemical processing, and power generation. For instance, in a chemical plant, the TRICONEX 2201 was implemented to automate a critical safety system that monitors pressure levels in reactors. By using this PLC, the plant reduced incidents of equipment failure and enhanced workplace safety significantly.

Competitive Comparison

When compared to other PLC models such as the Siemens S7-1200 and Allen-Bradley ControlLogix, the TRICONEX 2201 stands out in its dedicated focus on safety with advanced redundancy features. While competitors may offer higher speeds in processing, TRICONEX prioritizes safety and reliability, making it a preferred choice for industries where risk mitigation is essential.

Selection Recommendations

When choosing the TRICONEX 2201, consider the specific safety requirements of your application, as well as the compatibility with existing systems. Assess whether the modularity and redundancy of 2201 fit your operational needs, especially in environments that demand high availability.

Precautions

It is crucial to ensure correct installation and configuration of the TRICONEX 2201 to avoid any operational issues. Regular maintenance and updates of software and firmware should also be performed to maintain optimal performance.

We are your trusted partner, providing sales and technical support for TRICONEX 2201 and other automation spare parts. We offer special discounted prices. Please contact us, and we will be dedicated to serving you.

TRICONEX 2201