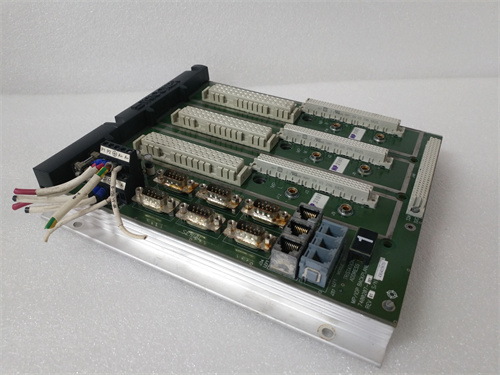

Product Name

TRICONEX 2101

Product Description

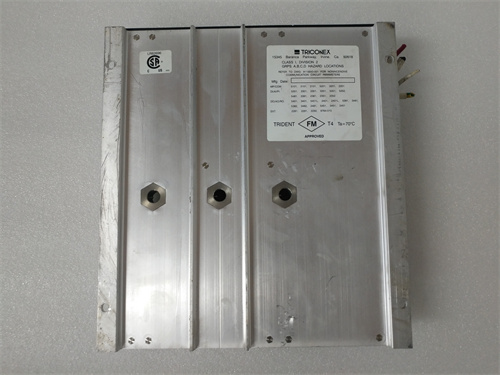

The TRICONEX 2101 is a robust and versatile programmable logic controller (PLC) designed for critical safety applications in various industries. Built by Triconex, a renowned leader in automation solutions, this model is known for its superior reliability and advanced control capabilities. The TRICONEX 2101 features a fault-tolerant architecture that ensures high availability and safety, making it an ideal choice for process automation where downtime is unacceptable.

Designed to meet stringent safety standards, the TRICONEX 2101 is equipped with a user-friendly interface and extensive diagnostic tools. This makes it easier to monitor system performance, troubleshoot issues, and maintain optimal operations without compromising safety.

Product Parameters

- Model Number: TRICONEX 2101

- Input Voltage: 24V DC

- Maximum Inputs: 64

- Maximum Outputs: 64

- Communication Ports: Serial RS-232/RS-485

- Operating Temperature Range: -20°C to 70°C

- Safety Rating: SIL 3 (Safety Integrity Level)

- Dimensions: Compact design for easy integration with existing systems.

Advantages and Features

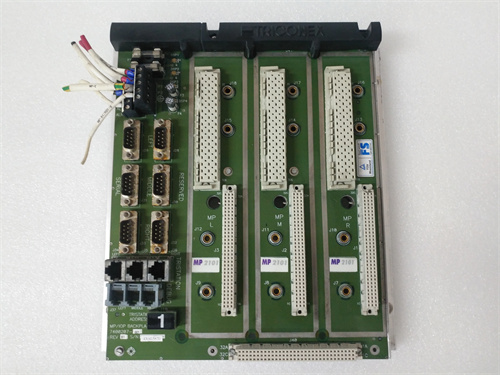

- Fault Tolerance: The TRICONEX 2101 is equipped with a triple modular redundancy (TMR) system, which ensures that failures in any single module do not compromise overall system functionality.

- High Safety Standards: This model meets international safety standards, providing peace of mind for implementations in critical process environments.

- Flexible Programming: The TRICONEX 2101 supports multiple programming languages, making it adaptable to various applications and user preferences.

- Robust Communication: Offers numerous communication options that facilitate seamless integration with other automation components.

- User-Friendly Interface: The intuitive user interface simplifies operation and minimizes the learning curve for new operators.

Application Areas and Case Studies

The TRICONEX 2101 is widely used across various sectors, including:

- Oil and Gas: Enhancing safety in drilling operations and refineries.

- Chemical Manufacturing: Ensuring safe operation of complex chemical processes.

- Power Generation: Monitoring and controlling systems in nuclear and fossil fuel plants.

- Water Treatment: Managing critical processes to ensure safe drinking water supply.

Case Study

In a leading petrochemical company, the implementation of the TRICONEX 2101 significantly increased operational reliability. By utilizing its advanced diagnostics, the company reduced downtime by 30% and improved safety measures, resulting in fewer incidents and enhanced compliance with regulations.

Competitive Comparison

When comparing the TRICONEX 2101 with similar PLC products, several advantages become evident:

- Unlike standard PLCs, the TRICONEX 2101 offers enhanced safety features and reliability with its TMR architecture.

- Competitors may not provide the same level of safety standards (SIL 3) required in high-stakes industries.

- The user interface and comprehensive diagnostic capabilities set the TRICONEX 2101 apart, enabling easier operation and maintenance.

Selection Recommendations

When considering the TRICONEX 2101, potential buyers should:

- Assess the specific safety requirements of their application—especially if dealing with hazardous materials.

- Evaluate the compatibility of the TRICONEX 2101 with existing system architecture.

- Consider future scalability needs and whether additional I/O expansion might be necessary.

Precautions

It’s essential to ensure that the installation environment of the TRICONEX 2101 meets the specified operational guidelines to avoid performance issues. Proper training for operators will also maximize the advantages of the system while maintaining compliance with safety protocols.

We are your trusted partner in automation solutions. We offer various product models including TRICONEX 2101 and other automation spare parts for sale and technical support. Special discount prices are available. Please contact us, and we will be dedicated to serving you.

TRICONEX 2101